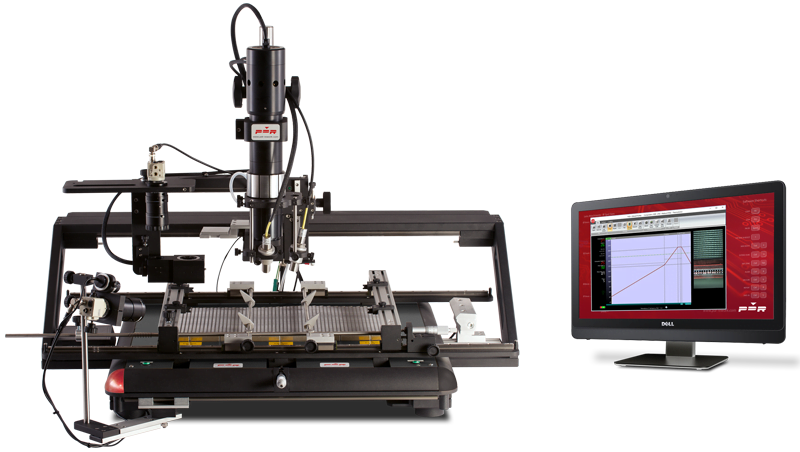

PDR-Rework - pseudo "BGA Rework Stations"

“Well-known manufacturers (they have a big name, for what I don’t understand)” from all over the world, they act as if they are gods, manipulating as they will, what they think that are a horde or herd of ignorant’s. They’re inventing unusable aberrant technologies, tools, devices (using pseudo-science, pseudo-technology) that electronics professionals are need for their own professional purpose.

After they invent their own aberrations, came the marketing team.

The marketing team act like a horde of predators, using the lowest possible social / moral / legal tools, that they have at their disposal, lies, cheating, disinformation and so on.

This combination between “well-known manufacturers” and that type of marketing, fore more than 40 years, was a recipe for success. But they are not alone… KUTZ-ERSA, Finetech… Are all in…

PDR-Rework review, you have some information on the internet… PDR-Rework have some videos (full of lies), they have international distributors where you can learn some characteristics (false / fake) and so on. Was more / different (more aberrant) information on the past, but they actualize his website (have realized some of the aberrations).

You will obtain best results to unmount and mount a BGA if you will use a barbecue, pizza machine or Santa Claus cousin, that buy garbage that manufacture PDR-Rework. And overall… will cost you a fraction of $70,000 that the PDR-Rework IR-E6 cost you. Until now, PDR claim 4,500+ clients hat was cheating. You can stop this if you’ll learn.

PDR-Rework claim / affirm all over the world they have the word’s best BGA Rework process, the world’s best approach to unmount and mount a BGA Chip. PDR-Rework argue his BGA Rework approach without common sense affirmations. Furthermore, PDR-Rework claim that don’t have air in movement (common sense point of view), don’t have nozzle for any chip dimension (common sense point of view), easy operating (lies, impossible to use).

Also, PDR-Rework affirm / claim That his PDR-Rework IR-E6 win some awards (that can be, but isn’t a positive point). Besides, PDR-Rework affirm that have a “proactive software” (only PDR-Rework and God know what mean that stupid words / invention, and at what are used…). The “proactive software” = aberration part chapter.

Furthermore, PDR-Rework claim / affirm that have an international distributor network that are at your disposition (my filing is that this “international distributors network” it is at his disposition). Generally, none distributor have more information on distributor website that have PDR-Rework on his website. They want only money for nothing. None PDR-Rework distributor have a real PDR-Rework review.

So… from what we’ll see on the internet seems that PDR-Rework approach for a “Real Professional BGA Rework Process” and a “Really Professional BGA Rework Station” is the best in the world. PDR-Rework make me laugh.

What PDR-Rework don’t know… It is the fact that they were so close of that… They even can’t imagine. But… They are not…

PDR-Rework observe the fact that the infrared energy can heat materials. Was… Thomas Alva Edison, when invent the bulb with carbon filament in 1879 before them. Before him was… The Neanderthals… Science say…

What they affirm / claim:

- Accuracy

- Uniform heating

- Shape of heating

- Powerful enough

- Best practice

- Software

- Automatic

- Yield 96%

- Split vision

- Process view camera

- Micrometer positioning

- PCB / board Fixture

- Cooling

- Weight

- Engineers

- Science

- Technology

- Support

- Awards

In 2012, PDR-Rework caught my attention and I want to buy a piece of that garbage. God bless my soul. I don’t buy it. In fact, I’ll put the science to work, to see if that all that PDR-Rework claim / affirm, have any scientific / technological argument or support. Doesn’t have. On the internet, until now real professional PDR-Rework review doesn’t exist… I decide that it is the moment to write one. A real professional PDR-Rework review. As a starting point to learn about nowadays BGA Rework Stations on the market, please use the home page. Here you’ll have another probably interesting point where you can continue to learn about real professional BGA Rework Station, a sister website.

In fact, to develop / manufacture this garbage PDR-Rework use the pseudoscience, pseudo technology, the worst ever practice. Sound like a very hard statements from my part. No, are not. The sciences / technologies give for that garbage, this statement. Let’s argue / demonstrate that statement… Let’s do some deep analyzing, some… reverse engineering and questioning the science and technologies about what we have here and write the only one PDR-Rework review.

Also, we will be questioning the veracity of the marketing affirmation to see how they sell 4,500+ pcs. Until nowadays.

1 – Accuracy – that garbage is one of the less accurate tool that the pseudoscience and pseudo-technology world can develop / manufacture.

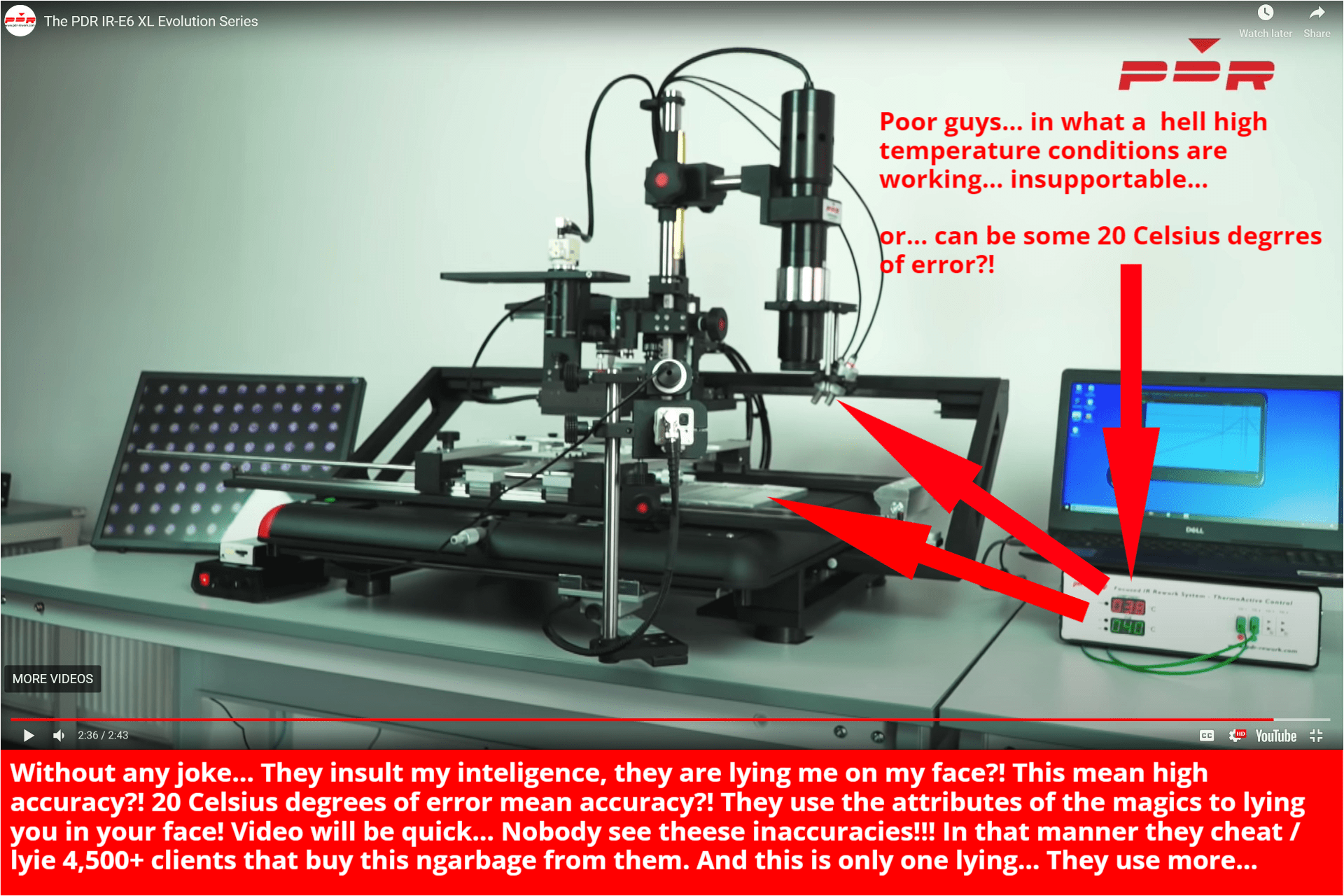

As you see in above image (I’ll saw my typo errors… I’ll not change again the image, in the future I will pay more attention… I promise…), you see that from start, only start the application, and it has at least… 20 Celsius degrees of error.

They use non-contact infrared sensors (thermopiles). I won’t go in to details, complete functioning of the garbage sensors (from Fluke… OEM – cheap, around $100). I’ll detail only one attribute of this kind of sensors. By the way… already it has another 2 Celsius degrees within the two sensors… Has not mounted the PCB on support… So… can’t tell me that are “after work”

Science time – Object emissivity. – click / touch for details.

So… Science says that the object has emissivity. The object emissivity varies from 0.01 to 1. So… This kind of sensors need calibration. The sensor is calibrated in the manufacturer to 0.96 (standard blackbody emissivity factor in practice).

What mean… “blackbody”?! Science time –blackbody. – click / touch for details.

In practice never… ever, you will have around 1. The “blackest material” ever invented by humans is “VantaBlack”… With an emissivity factor at 0.99965.

Science time – VantaBlack – click / touch for details.

So… let me give you some examples about working with thermopile / IR non-contact sensors. Think that you heat something that have 0.8 emissivity factor… You measure that 100 °C with a contact temperature sensor, temperature NIST traceable Certificate (NIST – world’s most valuated standards in the industry).

Science time – NIST Traceable certificate – click / touch for details.

So… Think that you heat something that have 0.8 emissivity factor… You measure that 100 °C with a contact temperature sensor, temperature NIST traceable Certificate (NIST – world’s most valuated standards in the industry). That mean that when you read 100 °C with a calibrated contact sensor, with a noncontact sensor you will read 80 °C.

Science time – 100 °C ≠ 80 °C. 100 °C are not equal with 80 °C (please believe me on my word…). Simple math…

On the analogy path… 0.7 object emissivity factor mean that you will read 70 °C, at 0.1 you’ll read 10 °C… and so on… extrapolate yourself…

Object emissivity of a BGA, for example, can vary from 0.2 to 0.85 according to the texture, color, material and so on. So… You need to calibrate the sensor for every BGA chip or for any of the chips you work with.

Conclusion… A non-contact / thermopile sensor are useless (must not be used) unless you compensate accurately the object emissivity factor, due to the fact that you’ll have the worst ever temperature reading value.

I’ll don’t speak about the fact that they use an OEM Fluke sensor due to the fact that originally the electronics that they use… was developed for K-Type thermocouple (contact sensor… K-Type thermocouple – worst ever type of contact sensors…).

When convert / step up to non-contact sensors, they search for one of the rarest non-contact sensors in the world that have output similar with T-Type thermocouple because they can’t (they are not electronics professionals, have nothing to do with electronics sciences…) use another type of sensors (I2C, SPI, Wi-Fi, Bluetooth and so on…).

So in that case, they use pseudo-science and pseudo technology to lie / cheat you – Chapter one – PDR Rework review.

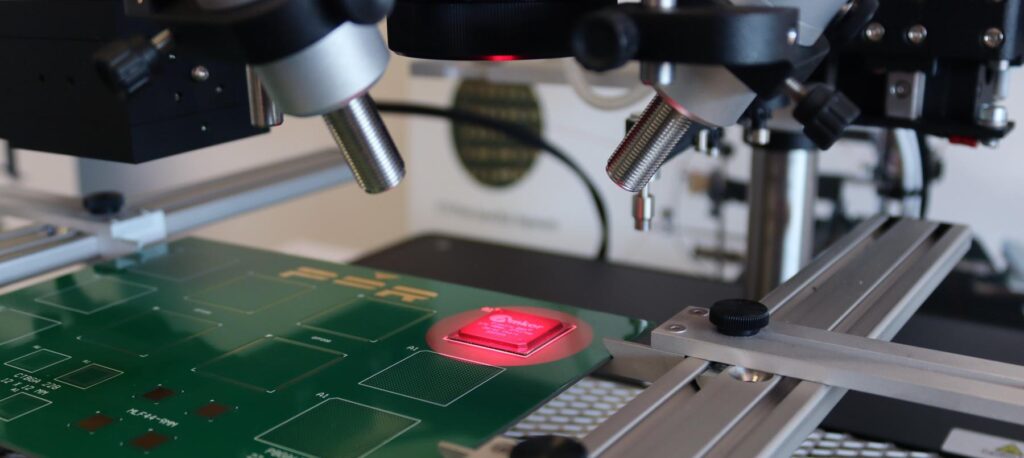

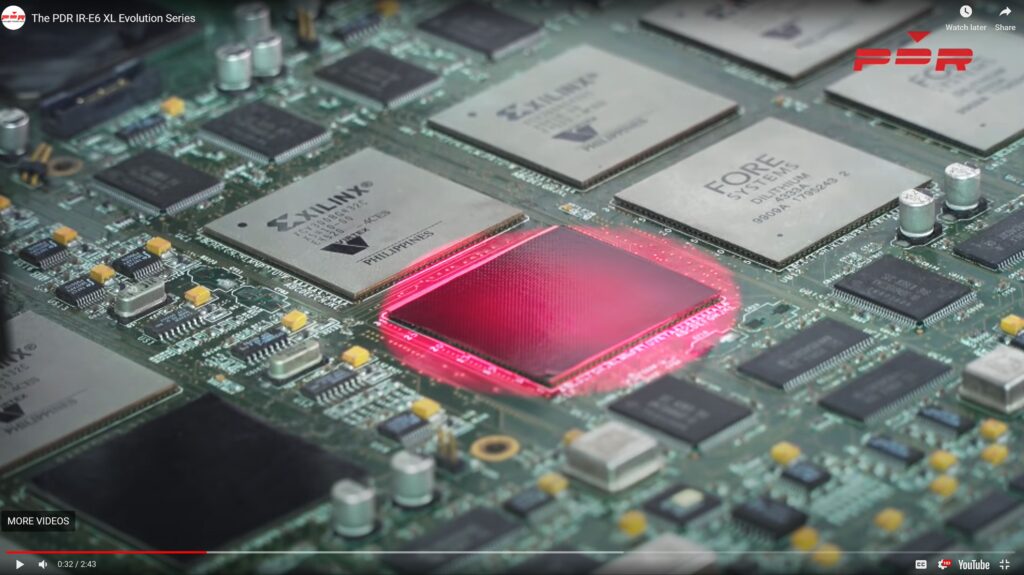

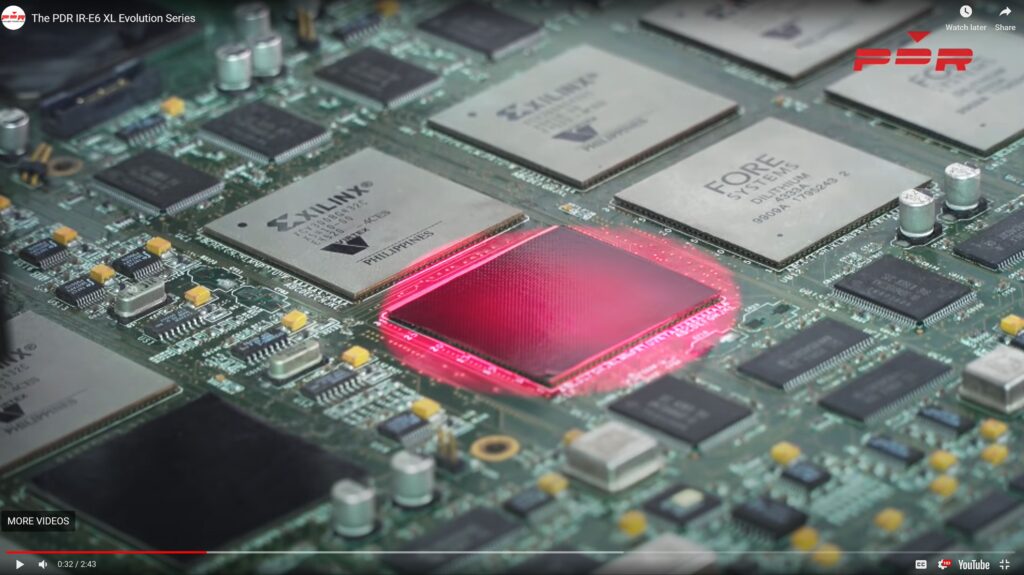

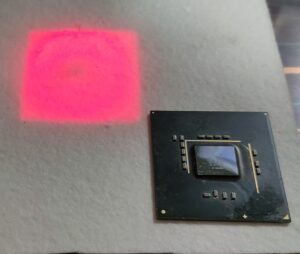

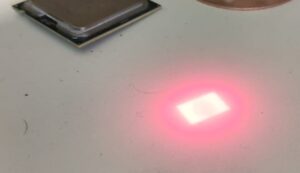

As we can see in the above image, the “focused light” aberration are… Round. In what a cruel world I live?! Was invented the round electronic chip?! Or the round BGA Chip?! I don’t hear that. From what I know, until now, the BGA and chips are square or rectangular. Is not… round. Well… PDR Rework use one more pseudo-science, the pseudo-technology, to cheat us.

On his page, PDR-Rework tells us that if we don’t like to be round… to put some aluminum tapes to mask the component. These gentlemen’s not have any shame / common sense?! At $70,000… some tape?! Some tape for… metallic top BGA object emissivity factor (black, you’ll can see on the image), another (aluminum tape) to shape the infrared energy… This guy’s… PDR-Rework… Sell tapes at $70.000?! Please don’t shut me that I’ll ask…

Conclusion – I’m convinced that $70,000 it is a little high-priced… tape’s business… price.

So in that case, they use pseudo-science and pseudo technology to lie / cheat you – Chapter three – PDR Rework review.

2 – Uniformity – Top Heater – These gentlemen have no shame, doesn’t have common sense, they are a real shame for the electronics industry.

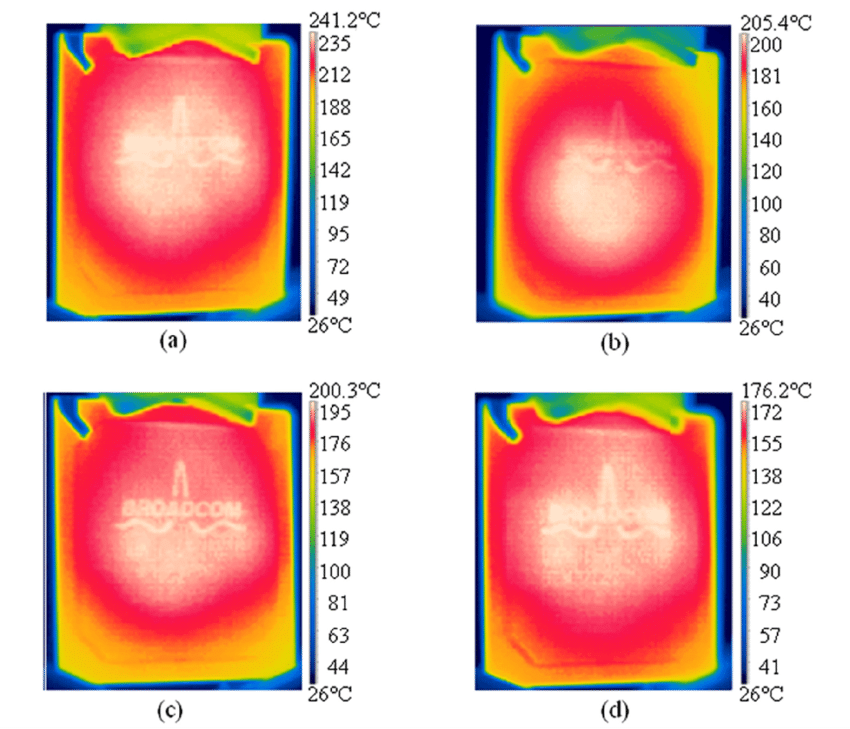

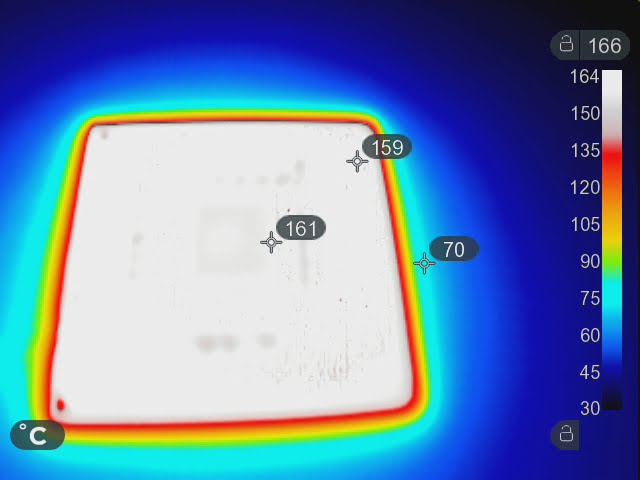

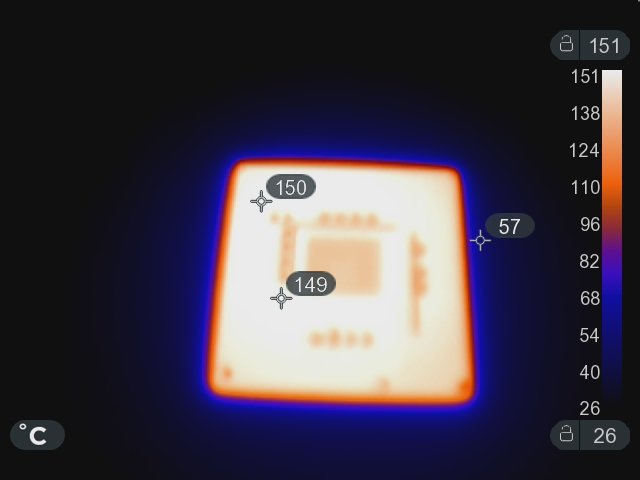

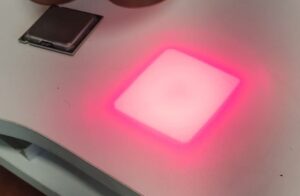

Above, you have the best example of non-uniformity ever in the world that are used to heat a BGA. In fact, if you will look with an infrared camera at the pattern from the above image (whitest / red in the middle and blackest / red in the corners), you’ll have something like that (right side images)…

The “professionals” that develop JEDEC/ IPC Rework profiles (even they – JEDEC / IPC don’t know why… but that will be another future story…), put some limits for center / corners temperature difference. That maximum limits are about 8 °C if you want to be sure that all balls will be soldered. As you will see in the images… in that cases the temperature difference from middle to corners can be around 53 °C.

Science time – 8 °C ≠ 53 °C – 8 °C are not equal to 53 °C – (please believe me on my word…). Simple math…

Let believe in what aberration develop JEDEC / IPC. Please don’t understand that I write that the PDR-Rework have this 53 °C of non-uniformity middle / corner of the chip… I don’t have the possibility to measure that… But I bet that their non uniformity middle corners are bigger than 53 °C! Or… not (because PDR Rework are cheating the BGA chip and the clients… you will read below with what they cheat…).

So… if you will have that 53 °C of difference between middle and corners of the BGA chip, at 250 °C in the middle and 197 °C in the corners, the BGA chip balls, will be soldered in the middle and not soldered in the corners. If you plan that solder the balls from corners, you will need to elevate the temperature from corners / middle, of course… So… 250 °C on the corners / 303 °C in the middle. You win… you will have all balls soldered… But… on an… Exploded / popcorn BGA Chip.

Conclusion – PDR-Rework don’t know what are doing. They heat with all price, with he’s patented, yes sir… patented pseudo-technology and patented pseudo-science “Focused infrared / light“. They don’t even know that are needed to be diffused energy (uniform spread across the entire chip area). Furthermore, they focus (laser like) the energy to obtain the most non-uniform possible pattern across the BGA chip.

So in that case, they use pseudo-science and pseudo technology to lie / cheat you – Chapter two – PDR Rework review.

In the above images, you have two examples to see what’s happening when you’ll heat the BGA / chip nonuniform. In the second / right image you’ll that even 0.44 mm (almost 0.5 mm) can be reach.

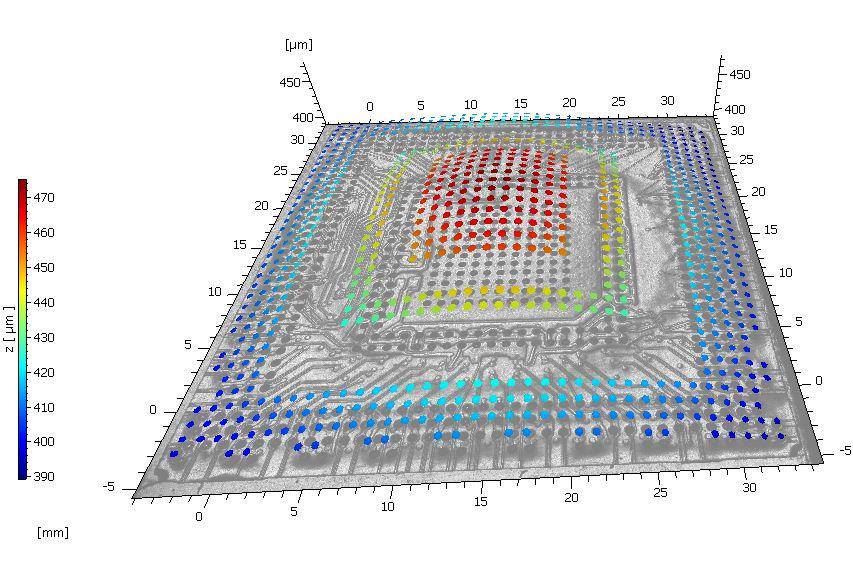

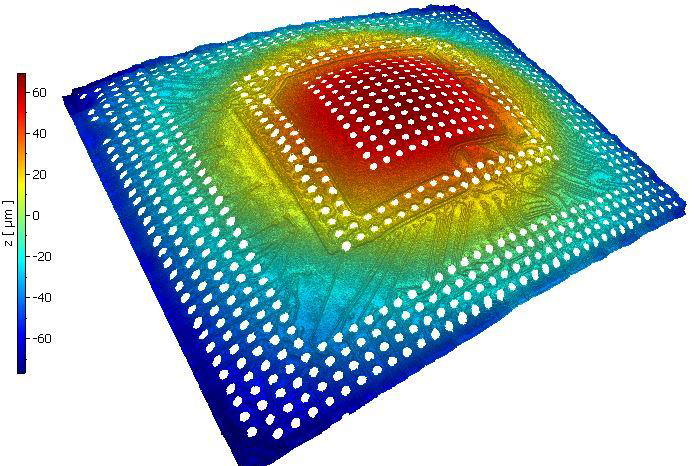

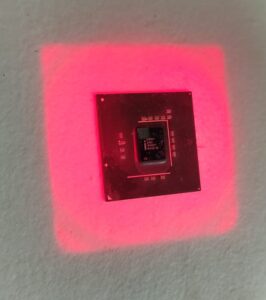

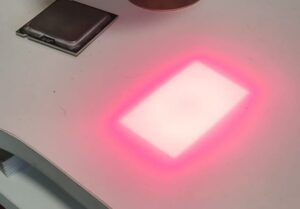

Next, I’ll give you an example about the fact that I know what I’ll write here. Next images don’t have any connection with PDR-Rework. That images are from my collection of images from my experiments about close to perfection temperature uniformity over the entire area of a 35 mm square BGA Chip.

In the above two images (that have nothing to do with PDR-Rework), you have a simple example of the almost perfect (2 °C / ±1 °C). When the right / correct science and technologies are used, any goal / yield it is possible. If you look with attention at the two images, you’ll see the almost perfect heating pattern that heat only the BGA Chip and outside from BGA Chip array almost no heating are provided. In that manner, the possible heat sensitive components close to the BGA Chip are not touched / heated.

3 – The shape of the electromagnetic radiated infrared energy – NIR / SWIR (for PDR-Rework general culture, infrared is energy / electromagnetic energy, it is not light).

As we can see in the above image, the “focused light” aberration it is… Round. In what a cruel world I live?! Was invented the round electronic chip?! Or the round BGA Chip?! I don’t hear that. From what I know, until now, the BGA and chips are square or rectangular. Is not… round. Well… PDR Rework use one more pseudo-science, the pseudo-technology, to cheat us.

On his page, PDR-Rework tells us that if we don’t like to be round… we have to put some aluminum tapes to mask the component. These gentlemen’s not have any shame / common sense?! At $50,000… Some tapes?! Some black tapes on top of BGA, to cheat object emissivity factor (black, you’ll can see on the image) and IR absorption by BGA, some metallic tape to mask adjacent components (aluminum tape) to shape the infrared energy… This guy’s… PDR-Rework… Sell tapes at $50.000?! Please don’t shut me, only that I’ll ask…

Conclusion – I’m convinced that $50,000 it is a little high-priced… tape’s business… price.

So in that case, they use pseudo-science and pseudo technology to lie / cheat you – Chapter three – PDR Rework review.

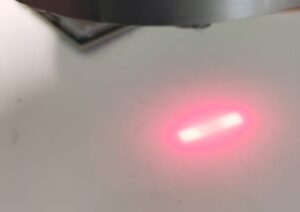

Next, I’ll give you an example about that I know what I’ll write here. Next images have nothing to do, don’t have any connection with PDR-Rework. That images are from my collection of images from my experiments (before alpha version) about near perfect infrared energy shaping square / rectangle from 5 mm to 65 mm continuous variable (I have round also… For round connectors, LED’s and so on).

In the above images, you have a simple example of the almost perfect infrared energy beam shaping. When the right / correct science and technologies are used, any goal / yield it is possible. If you look with attention at the images, you’ll see the almost perfect heating pattern that heat only the BGA Chip and outside from BGA Chip array no heating are provided.

In that manner, the possible heat sensitive components close to the BGA Chip are not heated / affected. No tape’s technology. My God… In what a $70.000 tape’s world I live. Ahh… On some image it can be seen a metallic top BGA Chip. That chip is an old server Xenon processor that I use it to test the infrared energy spot on metallic surface. I can heat without any problem and… without any tapes, any metallic BGA Chip, RF shield and so on…

4 – Enough power – That is one my favorite example where the science and technology are used in benefit of pseudo-science and pseudo-technology.

Some time ago… I find this image on my best friend (named Google). Seems to be a part from PDR patented technologies. So… you can’t copy their aberrations. Let’s analyze in deep this aberrational patent.

Somebody with some vague knowledge in optics (and with zero logic) pay a special attention on this patent development. In this case was used pure and hard science. Well done PDR-Rework, well done. That somebody… Pay a special attention to fine details… This detail name it is… Spherical aberration, in image… optic science.

Science time – Spherical aberration. Click / touch for details.

That spherical aberration MUST be corrected. If so… What is the problem?! What’s wrong here. All it is wrong. This correction has a price, and the price is the number of lens used to correct that spherical aberration. You’ll see later why… The spherical aberration, it is important in the visible spectrum (visible spectrum is a small part from electromagnetic spectrum).

So… this scientific guru that develop this aberrational patent, take in count the image (in the visible part of electromagnetic spectrum) and of course in infrared spectrum (infrared spectrum is another small part of the electromagnetic spectrum). The infrared energy / radiation / spectrum, it is invisible for human eye (so… I don’t know why the guru pay attention to that detail… spherical aberrations).

Science time – Electromagnetic spectrum / Visible light spectrum / Infrared spectrum. Click / touch for details.

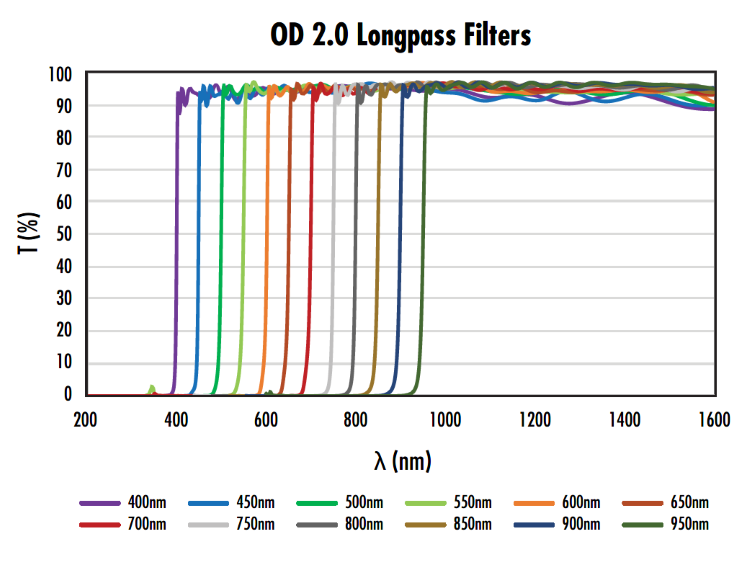

So far, so good. Above link, it is not complete, exhaustive information, but it is ok for our purpose. When you try to correct the spherical aberrations, you want to have a beautiful visible image (in the visible part of the electromagnetic spectrum). So far… so good. But… the genius behind this aberrational patent simply CUT (with a low quality Long Pass filter) almost all visible light spectrum. Here come the aberrations.

Science time – Long pass filter. Click / touch for details.

First the genius correct spherical aberrations in the visible spectrum (correct the visible image and make it beautiful) and after that correct (with 8 lenses and loose a huge amount of infrared energy…) the same genius cut almost all visible light (cut the beautiful image that corrected above and to passing only a small amount of red part of the visible spectrum).

So in the simple words… the genius make a beautiful image to throw them to trash – Aberration. The remaining red part of electromagnetic spectrum and the infrared part… Have no importance to be… beautiful. It can’t be… seen.

So… make something beautiful, thrash it, and loose energy in 8 lenses for that purpose. – Aberrational behavior. By the way… the shape / spot that I’ll have in my above images are made it with my patented process with only… one lens! 8 ≠ 1, please believe me…

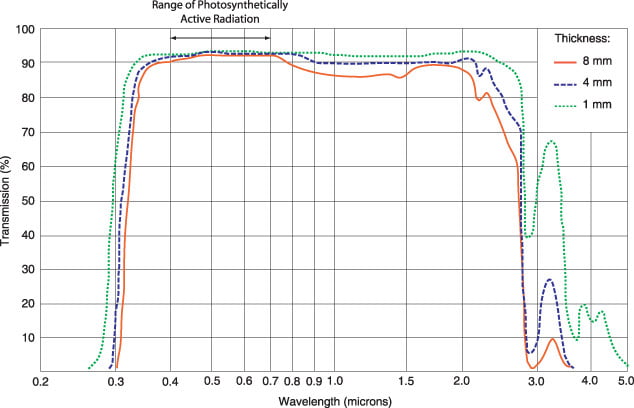

Let see what amount of energy loose in this patented aberration. Lens number – 8 or 9.

In the above image, you have a typical transmittance graph for Shrott borofloat glass that cover from visible part to infrared part of electromagnetic spectrum. As you see in every lens, they loose 10%.

Science Time – 10% X 8 lenses = 80% from initial energy are lost in the lens – (please believe me on my word…). Simple math… God bless our souls! But wait… The genius don’t stop here…

In the above image, you have a typical transmittance graph for Long Pass filters at various cutting frequency. Almost sure that PDR use one in 650 nm range. Please pay attention, above graph is for a quality long pass filter, about 5 % lost. In this world exist many types of long pass filters, majority with about 20% loosing at 3 mm thick (almost sure that type of long pass filter use PDR-Rework).

But… Exist only one type with 1.8%-2.2% loosing that NASA use (the same I’ll use). So… back to our business… Let take in account 10 % loosing.

Science time – 10% X 8 lenses = 80% from initial energy are lost in the lens. + 10 % losing in long pass filter = 90 % from initial energy… are lost!

The genius that develop that aberrational patent… Was a REAL GENIUS! As you see in the above image (the image with the patent), PDR use a halogen lamp to generate the initial energy. So far… so good. They claim that have the 150W consumed superpower. So far, so good.

Science time – 150W – 90% = 15W. Simple math.

The performance of the Osram gold-plated reflector bulb can be about 50 % in infrared radiation. 15W / 50% = 7.5W. That is a real aberration.

In fact, the genius behind this patent invent something unbelievable… As they don’t have enough power to heat even a fly… Invent the Round Holly Spirit blowing mode, to heat a BGA Chip.

Conclusion – I’ll think that it is very profitable to invest $70,000 to abuse Holly Spirit to heat a BGA Chip – Chapter four – PDR Rework review.

5 – Best practice. From the above approach (the holly spirit that heat a BGA Chip), it comes the worst ever approach on a Rework process. That worst ever approach took to highly risked operation, highly risked approach to heat a BGA chip, that put in danger entire boards / PCB’s VIAS.

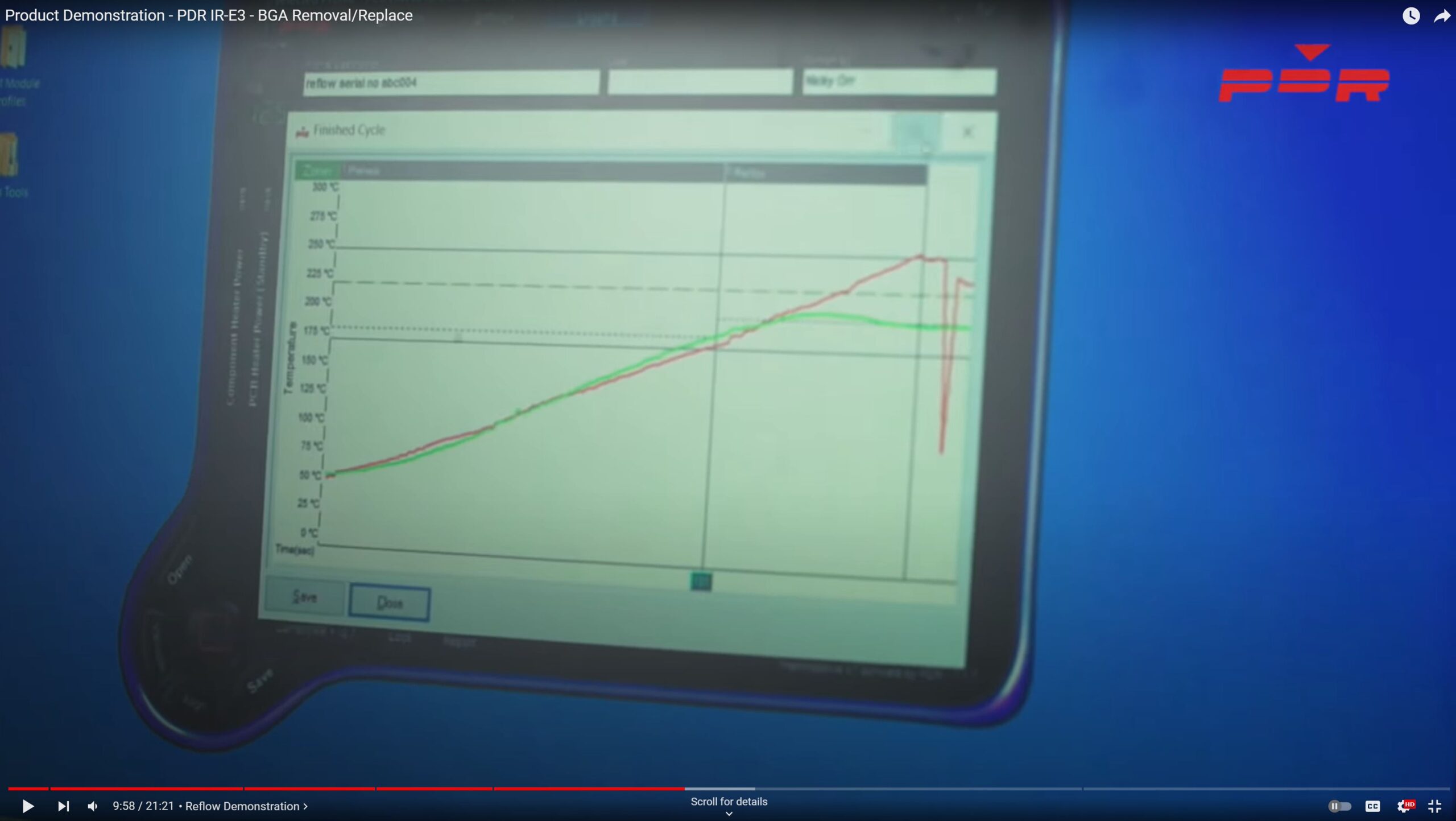

In the above image you can see something that at least on my head can’t fit. The green line that seems that correspond to bottom heater temperature at top point of graph it is over 210 °C !!! This is crazy. You will ask why. Let speak about… FR, Tg, VIAS and more… Only when I see the above image, I was horrified.

Now… when I develop this website, I saw that exist worse (if something can be worst approach…) approach that PDR-Rework approach to heat a board… ERSA Rework approach is worse! Click or touch the link for details. They heat the PCB / entire board… at 250 °C. God bless our soul!

THE BOARD / PCB – MUST DO NOT BE HEATED OVER 100 °C – READ BELOW WHY.

Science time – FR / Tg and the temperature – click / touch for details.

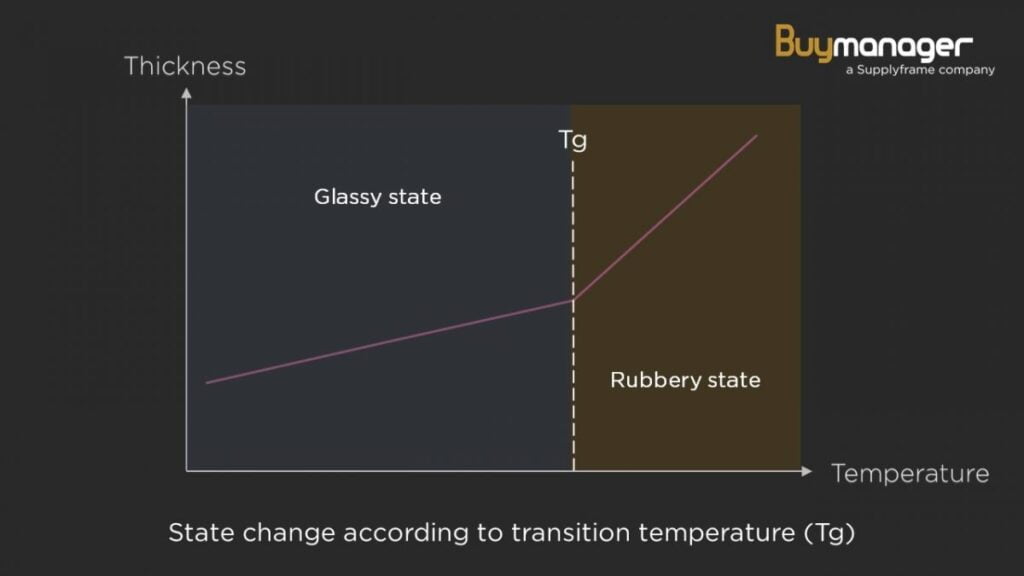

As you see in the above image, the TG point have incommensurate importance. The Tg represent the point of flection or… inflection. Tg is the point that the PCB change his state from a glassy (glass like / hard) state to a rubber like / elastic, state. This point is somewhere between 110 °C and 180 °C, FR (FFR-3, FR4… and so on…) standard dependent.

When the BGA is heated and cooled, expand and contract. So far… so good… or not. Short story. The PCB are manufactured from 3 materials, resin, fiberglass and copper, each of them with his particular / proper expansion coefficient.

Science time – You must believe me, if not… Google is your friend. Copper has an expansion coefficient, fiberglass have another expansion coefficient, resin have another expansion coefficient. The biggest problem with this expansion coefficient, Tg, glassy state, rubber state, FR’s… are the… VIAS (the small holes copper metalized that contact multiples layers of the PCB).

Chain theory – Chain theory say that the “chain will break at the weakest link”. Well… the weakest link of our chain are the VIAS. When the PCB was manufactured for the first time, when was reflowed, already was stressed close to his breaking limits. If first time the PCB / VIAS survive, second time will break and will generate intermittent failures, the worst defect in electronics…

Back to the 200 °C that PDR Use to do a “professional rework process”. The worst approach ever to do a rework process.

Conclusion – I’m sure that it worth it to pay $50,000 to have the possibility to have access at worst ever approach for BGA Rework Process – Chapter five – PDR Rework review.

I review in deep / on detail the most important aspects of this garbage that are sold as “Professional BGA Rework Station”. Until now, it is a real big shame for any real professional to buy that bullshit (remember… 4,500+ buy it…).

To continue, I will review in short mode the rest of the points that I mention on top of the page. Until now, I argue / demonstrate all my affirmations. If for the next affirmations you don’t believe me… well… Google is your friend to do your own research from, technological / scientific point of view.

Let’s Rock…

6 – Software – Seems that have implemented some kind of PID algorithm, anyway it is not the on / off control method. Anyway, is useless without the above points – Chapter six – PDR-Rework review.

7 – Automatic – it has no automations. Anyway, nobody from “all well-known / professional manufacturers”, nobody has automation / automatic. They all present motorized feature… like automatic features from a false fake / cheating, marketing point of view – Chapter seven – PDR-Rework review.

8 – Yield 96%. Nor even in his dreams can have that yield. But… 100% yield in aberration… it has – Chapter eight – PDR-Rework review.

9 – Split Vision – A misery that can be useful (exist another cheaper ways to center a BGA Chip). But to continue tendency in aberrations… All “well-known / professional manufacturers” name it “Beam Splitter“. In fact, from an optical point of view it is a “Beam combiner” the reverse of a beam splitter. That misery combine two images in one image for camera or for eyes, not split the camera or the eyes in two image.

This is a common / all mistakes due to the fact that all have no idea about what are speaking – Chapter nine – PDR-Rework review.

10 – Process view camera – Just like they already accustomed me, the worst approach ever (to look better a BGA ball’s best approach is if they put the camera at largest distance… on the moon for example…). They only copy / paste each and every error from one to another. In the future, you will see correct / the best approach for process view camera Chapter ten – PDR-Rework review.

11 – Micrometer positioning – Chinese garbage. PDR-Rework even don’t know what mean 10 um that they claim. Anyway… the 10 um or even 100 um have zero importance. When you mount a BGA and the tin it is in liquid state, appear the named superficial tension on a fluid… Google is your friend… That superficial tension will automatically center the BGA Chip in his place (will move the chip where it is his place) – Chapter eleven – PDR-Rework review.

12 – PCB / board Fixture – Fixed. PDR-Rework fix the PCB in the fixture. In that manner, when the PCB / board will heat, the PCB will expand. If it is fixed, will bend, and they will mount a plane BGA Chip on a round surface PCB. Aberration as they accustomed me – Chapter twelve – PDR-Rework review.

13 – Cooling – useless, they can’t cool anything with his “air knife“, another aberration… air knife… “Coanda effect”. Google is your friend for Coanda effect – Chapter thirteen – PDR-Rework review.

14 – Weight – For $70.000 – 100 kg it’s little aluminum misery. They even can’t sell aluminum at a reasonable price – Chapter fourteen – PDR-Rework review.

15 – Engineers – I don’t believe that PDR know the sense of that word… Engineers… But… PDR-Rework it is possible to have engineers in pseudo-science / pseudo-technology, almost sure that all they have PhD in that – Chapter fifteen – PDR-Rework review.

16 / 17 – for PDR-Rework the words science and technology have the only synonyms… Pseudo-science / pseudo-technology. Chapter sixteen – PDR-Rework review.

Enough – It disgusts me. But… I have the last two points, my favorite points… The only points that make me laugh… to not cry…

18 – Support – PDR-Rework support you… In what?! The answer start with… A.b.e.r.r.a… You name it – Chapter eighteen – PDR-Rework review.

19 – Awards – This word is a phenomenal word. This word closes a circle, the word that make the snake to bite his tail. If that word is not used on the PDR website, the circle can’t be closed, the snake can’t bite his tail. The name of the circle is… Ignorance. The name of the snake is… Promiscuity – Chapter nineteen – PDR-Rework review.

The word Awards close the chain of… manufacture / marketing / selling / using / crying a… garbage that have at his base… pseudo-science / pseudo-technology / aberrations / ignorance / promiscuity / lying / cheating / energumens.

Can you imagine… who is that energumens that give to PDR-Rework… awards?! But wait… I forgot… PDR-Rework have IPC Certificate. A piece of ass paper that are given by?! IPC ass paper certificates are given by… salesmen… That salesman pretend to learn you…electronics… sciences / soldering / selective soldering an… more. This thing… with the pyramidal game IPC ass paper Certificates of the salesman persons… I review on another page.

On this page I do not try to insult at anybody, all words that it is used, are a part from dictionary and describe best that place where was used. It is possible that are hard words for you, I’m sorry about that… But for 4,500+ persons that trust in sweet words spoked / wrote by money hungry ignorant peoples, that buy that garbage… I think that is harder for them.

Lying – cheating – false / fake marketing… are against the law in any civilized country. It’s only about time that some… “devil advocates” read this page. As that was a question of time (35+ years) that somebody write this page.

Final words about PDR-Rework – PDR-Rework took the words: absurd, aberration, promiscuity, ignorance and many more, to the next level, to the future.

If you read this page before, that will be corrected, I’ll inform you that the English language is not my native language. I’ll speak many more international languages… like… Spanish, science, technology, law, common sense, truth… Language that I’m sure that you’ll understand.

Best regards and thank you for reading this page.

P.D. – I forgot an important aspect for the stupid comportment of PDR-Rework – They offer paid (of course) course of Rework!!! – Aberrant.