Worst practice ever that all "well-known", "professional" manufacturers are using to lies, cheat... to steal you.

On above image you can clearly see worst practice aberrational, useless approach, popcorn BGA - energumens

When we speak about the worst practice, we speak about all "well-known", "professional" manufacturer's worst practice that used to manufacture something that they name it "BGA Rework Stations". What is incredible is the fact that they succeed to sell, for more than 35 years, more than 100,000 pcs. From that garbage's.

Let's explain for you some simple facts...

I’m a guy that come from a highly specialized / qualified electronic service field. Years ago, when I’ll was short in money, I’ll was obliged to buy my first multimeter (a Chinese, cheapest one). At that time I know that worth nothing but… was what I’ll have at that moment. I think… when I’ll grow up (in money), I’ll change it. After a while, I’ll change it with a Fluke – 289. In that same time, I’ll was obliged to buy my first oscilloscope (a Chinese, cheapest one). At that time I know that worth nothing but… was what I’ll have at that moment. After a while, I’ll change it with a Fluke – 190-202 SCOPEMETER.

On the same path as above, I want to buy a BGA Rework Station. At that time for me was a MUST-have. I’ll do a search on the internet for a Chines’ garbage – I’ll fund… nothing. I look at “well-known” / “professionals” manufacturers… First that I’ll see was the garbage unjustified prices for same worst approach, and the fact that are same miseries like Chines’ manufacturer’s worst approach. So far so good… But I need a real Professional BGA Rework Station. What can I’ll do ?! I’ll wait… For some years… Meantime I’ll study from scientific / technological point of view, best approach. That was between 2012 and 2017.

I’ll wait until 2017. In that year was enough waiting. In that years, between 2012 and 2017 I loose a huge amount of money due to the fact that I’ll don’t have a Real Professional BGA Rework Station. But I learn so many things in physics, material technology, best approaches and so on… in fact I learn / understand what I need from a real Professional BGA Rework Station. On 2017 still, I needed A Real Professional BGA Rework Station. On 2017, I’ll start few projects about BGA Rework stations, from two points of view – worst practice ever (all “will-known”, “Chinese”, “Professional” manufacturers) and best practice – science / technologies / logics / electronics.

In 2017, after that I’ll see that all “well-known”, “professional”, “Chinese” manufacturers does same things – copy / paste same errors, same aberrations, same worst practice ever… I decide to put in practice all my results derived from my past researches. I probe / test from theoretical and practical point of view, all and every worst practice / approach ever that all manufacturers use. That worst practice / approach ever, MUST not be used on electronics, on BGA Rework Stations. Below you’ll have my theoretical / practicals that I’ll discover about worst practice approach that all “well-known, professional, Chinese” have.

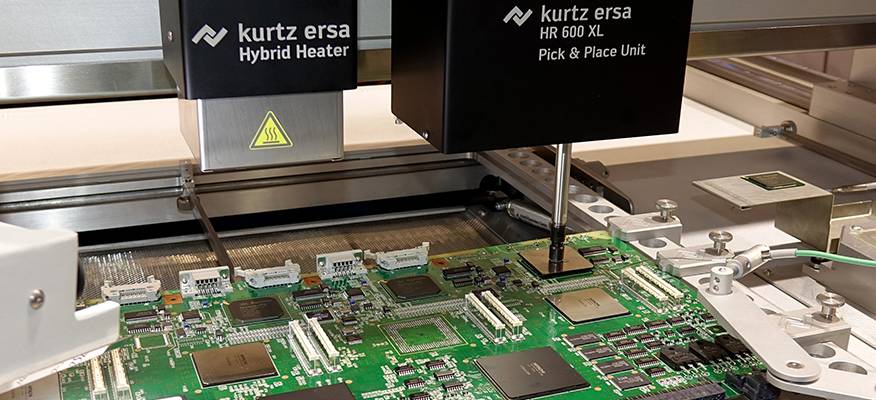

Top-heater - worst practice ever possible, a huge shame general approach.

Above you’ll have the shames “hybrid” top-heater worst practice approach from KURTZ-ERSA – “well-known” garbage manufacturer. They combine two worst practice in one heater, hot air / gas (nitrogen capable) and “black-IR”. Not only that image (I’ll can’t put here all images from internet, Google it’s your friend to see the worst practice).

When we are speaking about bottom-heater on a BGA Rework Station from the actual, the worst practice ever approach, we’ll speak about the pseudoscience, pseudo-technologies, bad understand of a real professional Rework process. All manufacturers think that are appropriate to heat a PCB / board with any heating device. They think that with a pizza machine, popcorn machine or Santa Claus cousin are appropriate device for that purpose. False. Even that all that garbage are capable to un solder and solder something, that not mean that that approach are indicated to be used or have anything to do with best practice, and it works after.

Bottom-heater - worst practice ever possible, a huge for that shame general approach.

Above you have one Chinese example of the worst practice ever, incontrollable “black-IR”, nonuniform heat among the PCB “two zones” worst practice approach ever (I’ll can’t put here all images from internet, Google it’s your friend to see the worst practice).

Same approach here, the worst practice ever approaches. They use “Black-IR”, hot air, hot gas (nitrogen- an aberration that MUST don’t forget to review). PDR-Rework have some intuition but they… generate let say 100W of energy and after that they generate that energy… throw 90W / 90% of that 100W to trash (heat 8 lenses) on his “focused light” aberration head and less 10W – 10% arrived at chip that must be heated. Read with attention all information on this website and sister website bga-rework-station.com

Google is your friend to see more aberrational ways about what they (well-known, professional manufacturers).

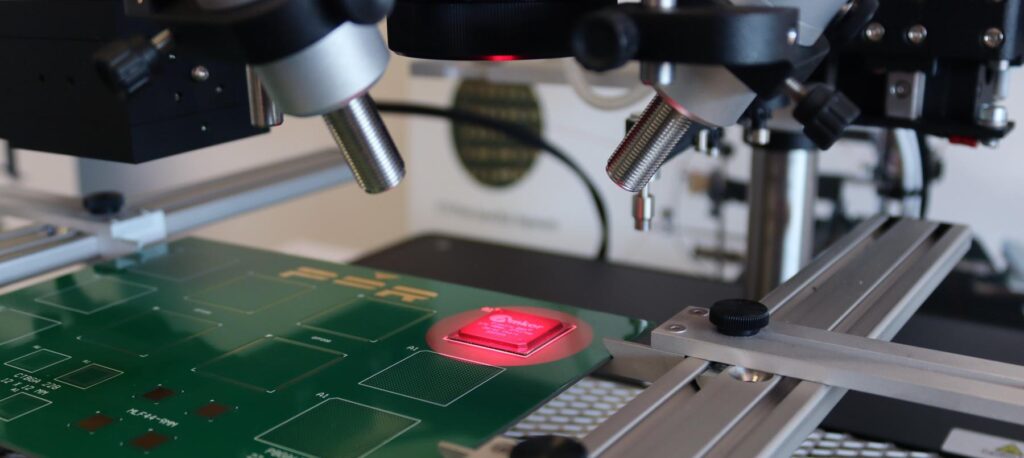

Temperature measurement and control - worst practice ever possible, a shame general approach.

Above you’ll have the worst practice approach ever for non-contact – IR, temperature measurement sensors, the PDR-Rework approach(I’ll can’t put here all images from internet, Google it’s your friend to see the worst practice).

But PDR-Rework are not alone, they un non-calibrated non-contact IR (at last ± 25 °C –) sensors for temperature measurement. About 50 °C error accuracy!!! As I’ll say… they’re not alone, all… but all “well known, professional, Chinese”… all they are using inappropriate thermocouples (K-type) for contact type of temperature sensing or non-compensating non-contact IR sensors.

At a moment, I wondered if I live in an “amputated brain apes planet”. For me, it is an incompressible situation. A whole world is incapable to think?! All they can’t stop from money hungry competition and think?!

Bottom-heater, top heater, temperature measurement and control, the worst practice used in all that, all this will affect the (lowest possible) quality of BGA Rework Process in consequence the quality of what "well-known", "professional" manufacturers develop / selling you as BGA Rework Stations. In the first place, before you buy that garbage's, you Must know important facts that will screw up your future work.

Resin + glass fiber PCB / Boards, most common PCB's.

All “well-known, professional, Chinese manufacturers” are complete ignorant, are using the worst practice ever approaches due to the fact that they don’t know anything about technology, science and so on that are behind of PCB manufacturing. That is a pure and simple aberration. They heat the PCB at 200 °C to 260 °C!!!

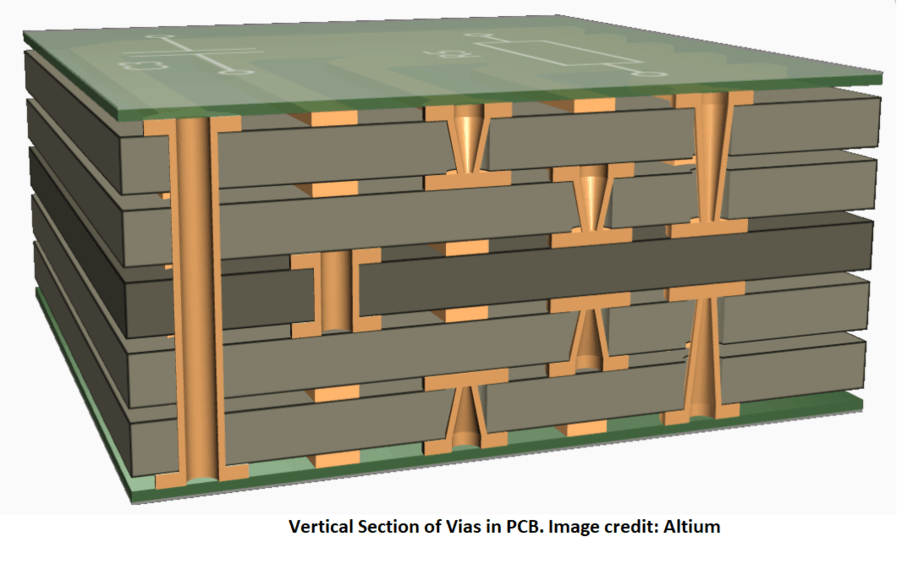

They believe that a PCB are indestructible. Thar says for them the pseudo-science, pseudo-technologies worst practice and so on. They don’t know anything about broken vias, that is normal, they don’t have any connection with electronics sciences.

A PCB / board MUST NOT be heated above 100 °C. Point.

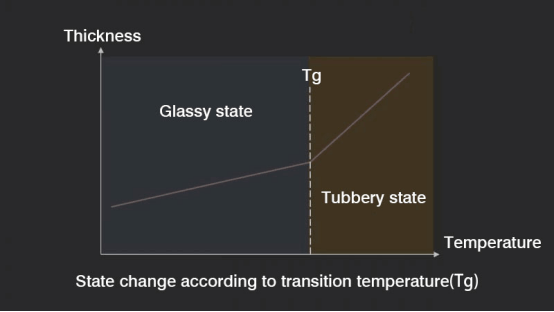

T-g-point - something that are strange thing for all they...

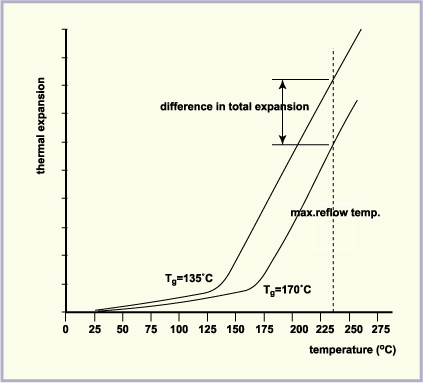

If we go into detail about PCB’s, we need to speak about Tg – point. This point has a huge importance when we think about heating a PCB. That point is a must, even “not touch” Tg – point when we speak about temperature and PCB. Almost all the time when we work with PCB, we don’t know the value of that Tg – point. If we want to eliminate almost all risk to break the PCB when we heat it, we need to be sure that we are not even close to that Tg – point.

For PCB security, we must keep the maximum temperature when we heat a PCB under 100 °C and maximum 100 °C. That thin (PCB security, best practice) for all manufacturers not exist.

They heat the PCB at 200 °C to 250 °C – worst practice ever.

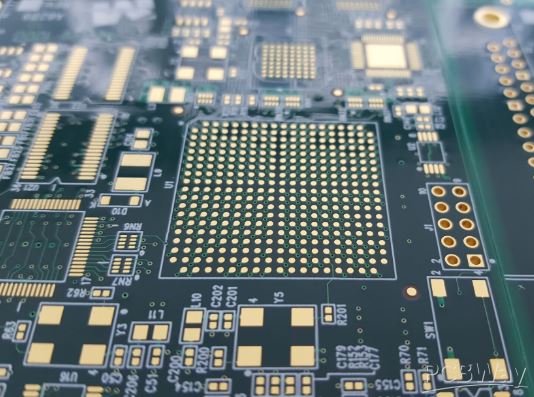

Let speak about VIAS, the little copper plated holes.

In this life, on this planet – Earth, exist many theories. One of them is the next theory. “A chain will break at the weakest link“. On our case, the weakest link is the vias. Another theory from same life / same planet say that he stress applied on a system, are proportional with the value of that stress.

But that theory about best practice (smaller possible stress) are unknown for that amputated brains apes – (“well-known, professional, Chinese manufacturers”)

But for all of them, it is important worst practice ever approach.

Over 100 °C to 260 °C, are the high risk temperature range.

Let speak about inertia of uniformity on PCB temperature.

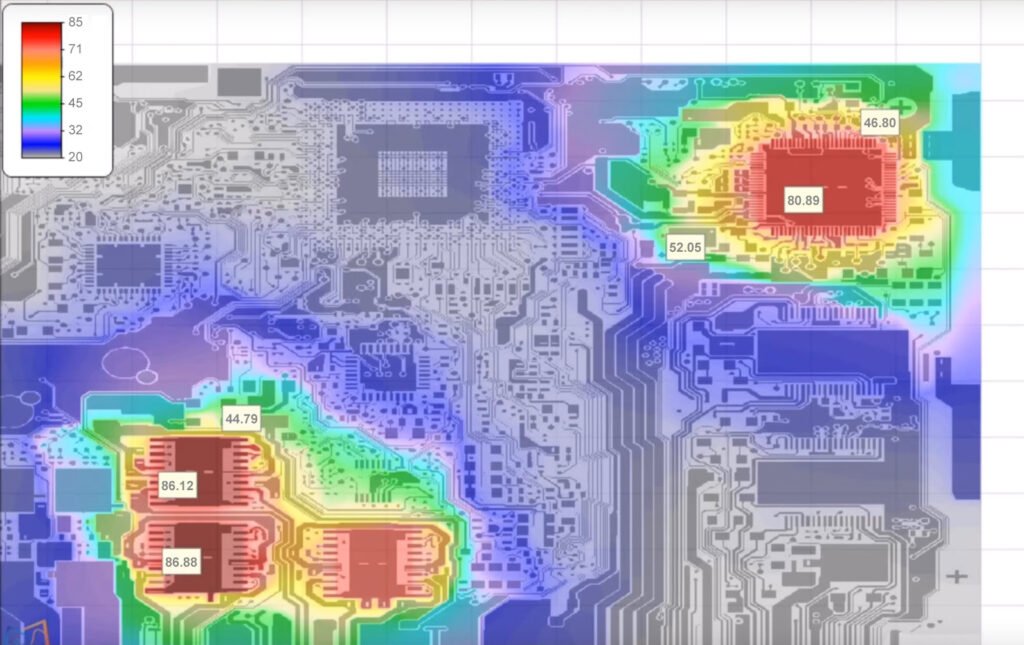

Almost sure that you know (if not… Google it’s your friend) the PCB manufactured from FR-4 composite have – Copper – 400 W/m2K, resin + glass fiber – 0.4 W/m2K thermal conductivity. So far, so good.

400 W/m2K mean – one of the highest thermal conductivity material and 0.4 W/m2K – mean one of the lowest conductivity material (thermal insulator material). But for all “well-known, professional, Chinese manufacturers” and standards developers, that parameters are unknown. In fact, when the worst practice ever approach is his approach…

We must study the thermal conductivity before standards.

100 °C maximum PCB temperature on Rework Process.

On same planet Earth exists the common sense, best practice. That things are opposite to the worst practice ever approach. The common sense tell us that if we don’t know something, we not touch it. Well… On the majority of the occasions, we don’t know the Tg – point of the BGA. The common sense tell us that we need to use the lowest Tg – point that we know. But that is the best practice approach.

“Well-known, professional, Chinese manufacturers” don’t know that, aren’t important for them. They heat the PCB with all price, the worst practice ever approach = more money ever.

We would go on “rubbery state” of the PCB. Temp. > Tg -point.

Materials, texture, colors - have a huge importance on PCB.

For “Well-known, professional, Chinese manufacturers” that thing… with materials, textures, colors are equal important as all another scientific things, zero. On their worst practice ever, money making competition, forgot about all. For them, when are using non-contact IR sensors (Emissivity factor dependent), that things are not important.

For another that use contact sensors… the same zero importance it has. It is not important the texture of the PCB. They can measure the PCB temperature even without thermal contact paste.

They use holly spirit as interface between sensor and PCB.

Materials, textures, colors, have huge importance for PCB.

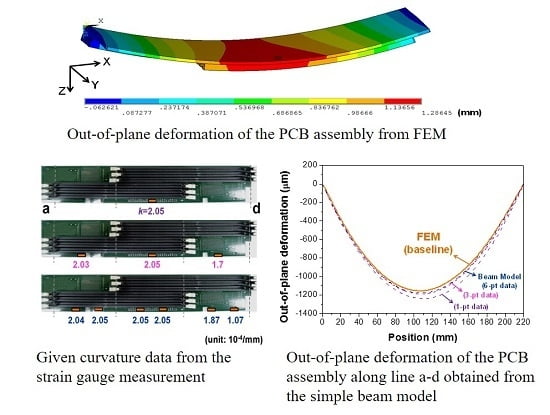

Board expansion when are heated, a bent PCB to mount...

… a plane BGA / chip. Even that the bending of PCB are difficult to see with the naked eyes, that bent exists and generate the worst practice ever approach when we try to solder the BGA / chip on the PCB. The initial contact between PCB and BGA are not uniform, in consequence the balls / pads are non heated uniform. If that appear, the migration of tin will occur, resulting in short circuit between various pads from PCB / BGA. Of course, we need to not forgot about the fact that they use direct heating methods. Another example of brainless of “Well-known, professional, Chinese manufacturers”.

We need to pay attention to bending PCB when are heated.

Dilatation / contraction, propriety of PCB, special attention.

The lack of knowledge of “Well-known, professional, Chinese manufacturers”, generate the worst practice ever approach when they heat with any price the PCB. Direct convection heating (hot air / Black IR / hybrid and so on…) that all they are using to heat a PCB are inappropriate method. That approach is an uncontrolled process due to the fact that the air (that is the heat transport medium), is the worst ever energy transport medium. Air have 0.02 W/m2K thermal conductivity. In fact, the air is one of the best thermal insulator. Air are used, in many, the best approach over the world to insulate against temperature difference.

Need to pay special attention to with what we heat the PCB

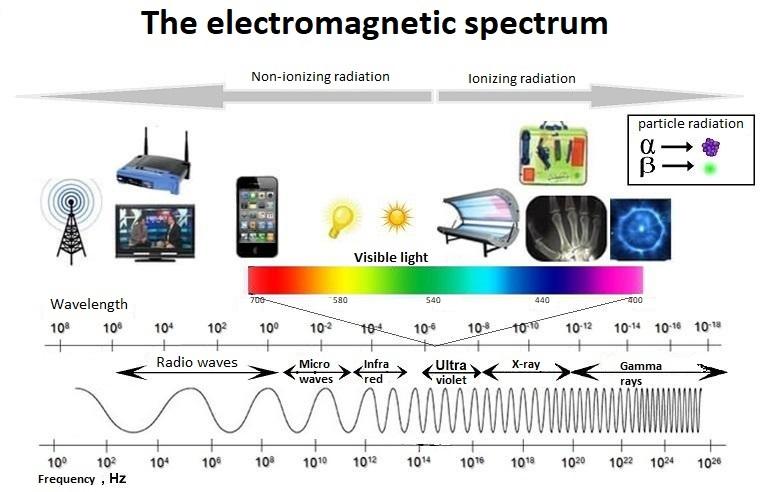

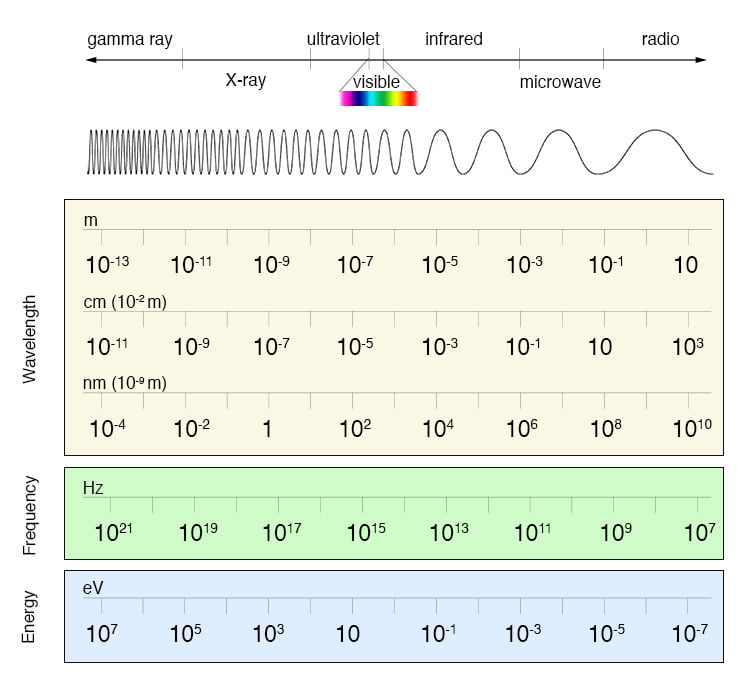

Electromagnetic energy vs convection heating of PCB / board.

The conventional heating worst practice ever approach that “Well-known, professional, Chinese manufacturers” are using, the direct convection, is an inappropriate approach. But… now, ve are already immune to their aberrations.

It is a MUST the best practice ever approach that mean direct electromagnetic energy transfer, after that the PCB receive that electromagnetic energy, will self heating (will produce himself heat). That way, it’s the only way when we think about heating a PCB, but they… they have the brain missing due to the fact that some aliens amputee their brain. But… we’ll buy that garbage’s.

We need to think about the right ways to heat PCB / Board.

Chose the right part of electromagnetic energy to heat the PCB

In fact, direct convection, direct energy transfer, each are methods to transfer electromagnetic energy from a point to another. As always, exist many ways to approach a target, worst practice, and best practice. What I can’t understand is the fact that they, “Well-known, professional, Chinese manufacturers”, take / use the worst practice ever on their all approaches. I wonder how it is possible that fore more than 40 years they are unable to cache only one… Only one good practice (I’ll don’t speak about best practice…). All that are inadmissible on the electronics industry / manufacturing. We need to wake up and think… Thinking… Doesn’t hurt.

Choosing right approach to heat PCB / board, it’s a MUST.

Worst practice ever approach takes you on the bet.

After that we read all information from this page, we can extract some conclusions about worst practice..

- The first and inevitable conclusion is that I’ll need a huge improvement for my English communication language.

- The second and inevitable conclusion is the fact that if we use the worst practice ever approach, we’ll go into bet games, where the chance to do a real Professional Rework Process are zero / 0. Even we will have some chance to solder some BGA / chips on the / PCB / boards, that doesn’t mean that the PCB / board will work. And if… the PCB / board will work… Well… never ever, we will have the warranty about how time will work.

- The worst ever, way / method / approach / practice that we use on PCB / board heating is an important factor that will have a huge influence on the quality of our BGA Rework

- We must think about all that is writing on that page, about all that are writing on that website and on the sister website BGA-Rework-Station.com

- If we don’t think, learn, understand, we buy with price policy, all that before buying a garbage, after that we will buy that garbage… we’ll pay.

- The worst practice ever approach, it is that we buy for price or whatever any other that scientifically, technologically approach, after that we almost sure we take in account that we’ll through the money to trash.

Best practice ever approach takes you at 100% yield.

After that we read all information from this page, we can extract some conclusions about best practice..

- I promise that after that I’ll finish this draws, I’ll put all websites in the cleanest American language possible, I will ask a somebody for that. Until that moment, if you speak science, technology, electronics… You’ll understand what I write here.

- It is a must to ignore all the worst practice ever approaches on that world. It is a must to put in balance all that “Well-known, professional, Chinese manufacturers” energumens manufacturers, that act like an amputated brain monkeys in his fight to sell us the worst ever pizza / popcorn machines or… Santa Claus cousin.

- We need to ask them to prove all stupid affirmations that they make all over the internet. We need to understand that an affirmation must be proved. Without proof, remain non-value affirmation, and we must avoid to pay attention to that.

- When we think, analyze, learn, document’s us before that make a considerable inversion, we not only are wiser, but we protect our pockets in front of without common sense, lairs, cheaters, that invade the most wide source of information… The internet.