Worst conclusions

Worst conclusions about 35 + years of errors on BGA Rework Stations approaches / selling / buying. Pseudo-science & technologies Top – heater Nowadays “well-known, professional, Chinese manufacturers” use same copy / paste errors based in direct temperature transfer method. All, hot air, Black-IR, MWIR, Hybrid and so on techniques, use that world’s worst ever […]

Errors

The errors are the real problem that all “well-known”, “professional manufacturers” have, is the fact that they use inappropriate technologies to heat a BGA. That inappropriate technologies that they use to heat a BGA (a highly delicate / complex process), are used with success in other applications like cook tops, rooms heating, pizza machines, popcorn […]

Tg point

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Tg point

Tg point of PCB – the universal error in Rework Process. That error must / can be avoided. The Tg point, in the electronics assembly / soldering industry, represent the world’s worst ever practice approach. Nobody, but nobody, pay attention to some scientific, technological point of views. All “well-known, professionals, Chinese” manufacturers – money hungry […]

BGA / chip

BGA Rework Station – BGA / Chip – top-heater – Direct Energy Transfer – DET® – probably the best practice ever approach. An almost perfect BGA Rework Process – software – Alpha control – ECO version, ± 1 °C – Top-Heater, ± 2 °C – Bottom-Heater. Above image are from early tests (early alpha versions […]

BGA / chip

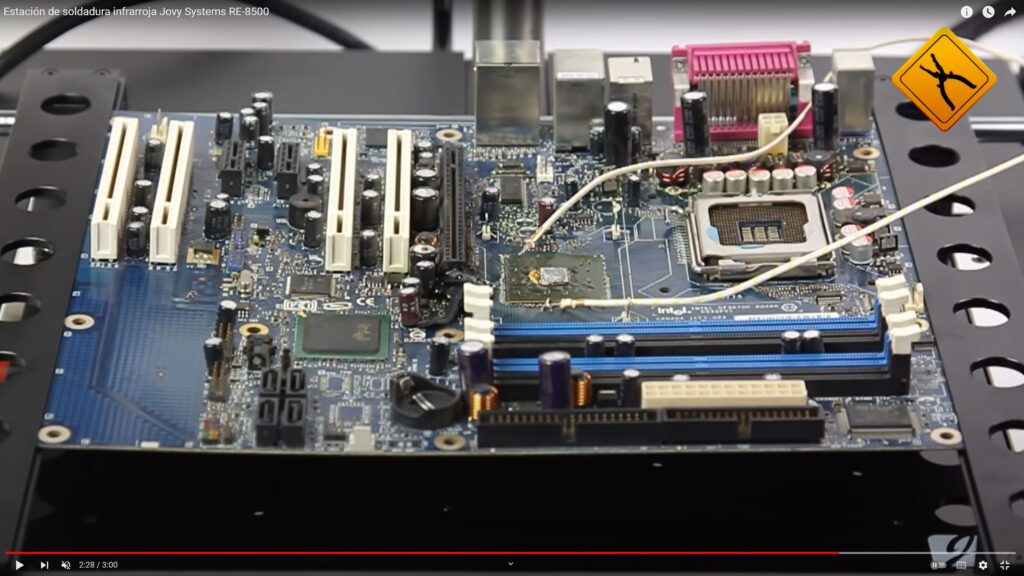

BGA Rework Stations – BGA / Chip – top-heater – worst practice approach “well-known, professional, Chinese” use. Worst approach for heating of BGA / Chip. Convection / “Black-IR”, “Focused Light”. All “well-known”, “professional, Chinese manufacturers”, use only the worst approach to heat a BGA / Chip. They don’t know anything about science, materials technology, best […]

PCB

Best practice PCB / board policy. Temperatures, accuracies, elasticity, control, electromagnetic energy… and more… When we speak about best practice PCB / boards on BGA Rework Stations or Rework process, we need to know some important facts that we MUST respect. Below we’ll speak about materials, temperature, Tg – point, FR-*’s, VIAS, uniformity and more. […]

PCB

Worst practice ever that all “well-known”, “professional” manufacturers are using to lies, cheat… to steal you. On above image you can clearly see worst practice aberrational, useless approach, popcorn BGA – energumens When we speak about the worst practice, we speak about all “well-known”, “professional” manufacturer’s worst practice that used to manufacture something that they […]