Finetech review

“Well-known manufacturers (they have a big name, for what I don’t understand)” from all over the world, they act as if they are gods, manipulating as they will, what they think that are a horde or herd of ignorant’s. They’re inventing unusable aberrant technologies, tools, devices (using pseudo-science, pseudo-technology) that electronics professionals are need for their own professional purpose.

After they invent their own aberrations, came the marketing team.

The marketing team act like a horde of predators, using the lowest possible social / moral / legal tools, that they have at their disposal, lies, cheating, disinformation and so on.

This combination between “well-known manufacturers” and that type of marketing, fore more than 40 years, was a recipe for success.Please believe me… You can do what that garbage’s does with a pizza machine, cook top machine, popcorn machine and… even with a barbecue + some temperature sensors and some timers.

And overall, you’ll cost a fraction of that garbage’s price.

“Well-known manufacturer” all over the world, act as if they are gods, manipulating as they will, what they think that are a horde or herd of ignorant. They invent technologies, tools, devices that electronics professionals must use for their intended purpose.

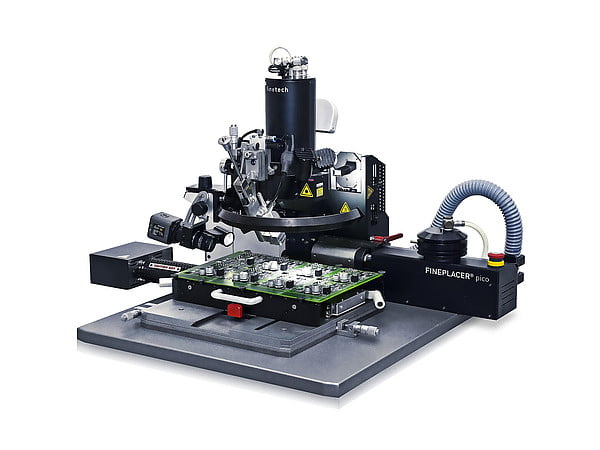

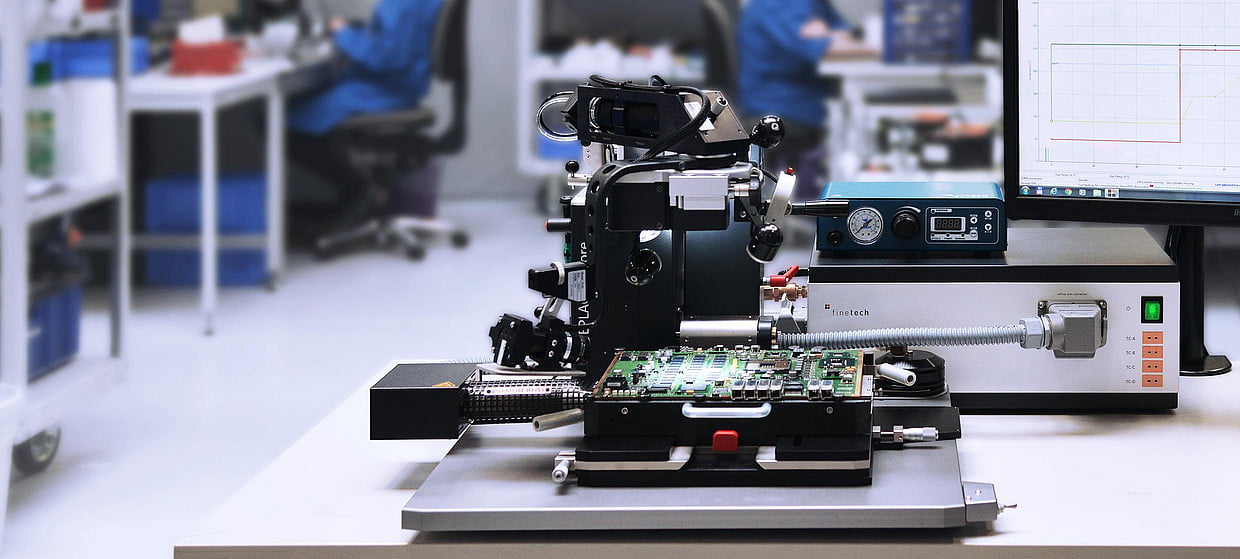

Finetech review, the “well-known” Finetech manufacturer and their garbage’s, in general – reviewed.

Fintech, as PDR-Rework, as Kurtzz-ERSA… claim, quality, the word’s best ever approach, high yield, professional, expert, courses, world’s best support… You name it all… That these thefts claim. Finetech claim all that with the only purpose that stole money from you. No proof about his affirmations.

But pay attention!!! They don’t force you to buy his garbage’s! They only cheat your ignorance, misinformation, undocumented, credulity.

“This one will cost about $70,000. And if I add a dispensing module, it will cost about $84,000.” Cry, a guy on a… forum. God save our souls.

1 – Wrong practice ever – Hot air / hot gas (nitrogen capable) – worst ever aberration that can be used to heat a PCB / board and / or a BGA / Chip. Even to heat, high mass RF shield are the worst approach. Let see why?!

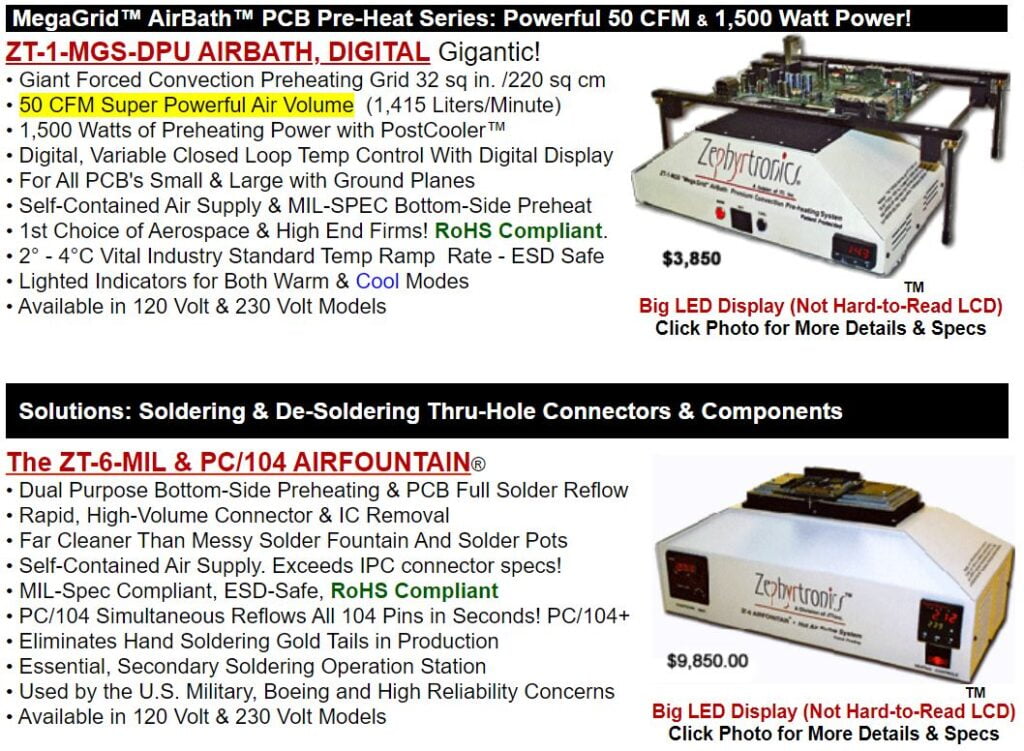

I’ll start this review with some interesting facts. Bottom I’ll put two images, left side (first on mobile) are from another “well-known manufacturer” of garbage’s… Zephyrtronics. As you can see with long, long time ago… This… Zephyrtronics invent hot air “Airbath®, Airfountain®“. So far, so good. Finetech invent hot air… Jacuzzi®. These gentlemen’s, once upon a time, start to copy / paste one from another all aberrations. These things, make me laughs to keep from crying. Honestly, I don’t know who at who copy / paste that aberrations. But both selling you, and you’ll buy that aberrations. I’ll speak about hot air / hot gas (nitrogen capable policy) on ERSA garbage’s review. I’ll do it again.

This garbage’s manufactured by Finetech are somehow different from ERSA garbage’s. Finetech use hot air for top heater and hot air for bottom heater. Not only that use aberrant pseudotechnology once, Finetech use twice that aberrations. But… I think that Finetech even don’t measure PCB temperature directly (I think that are trying to calculate temperature with some voodoo equations). What is sure it is the fact that they use K-Type thermocouples (I think that they are on bottom…). So… exist same Tg – point, that seems that are not important for Finetech. It sold to you garbage that oblige you to play on casino, it obliges you to RISK, your PCB / board and your BGA / chips.

Now, when I’ll write these reviews and try to organize them, I’ll set that all (three reviews until now) have in common one error, the biggest ever error, that make it possible the fact that for more than 35 years it is possible that all garbage that are named BGA Rework Station can be sold / bought, all over the world. For me, it is unbelievable that an entire world doesn’t know to heat a PCB / board. Heating a PCB / board, it is the basic and the most important approach in BGA Rework Process. The way that you’ll heat the PCB / board are the first parameter / best practice / must-known to achieve the 100% repetitiveness / 100% yield.

The amazing situation is not that the users of “well-known manufacturers” BGA Rework Stations, doesn’t know to heat a PCB / board, the amazing of the situation is that all “well-known manufacturers” himself even they don’t hear about Tg – point. What a shame, what a shame for an entire industry. Promote tools that destroy PCB / boards are the ever worst, shameful situation for all self-named. “Well-known manufacturers”. You, that brought this garbage’s from the today’s days market are blindly trust in their affirmations. That was a huge error. This is the dark side of an entire industry.

I can understand the fact that all world manufacturers, with the marketing / publicity, manipulate the consumers / clients with some trues affirmations and some little trues gaps… But what I can’t understand it is how an entire world professional industry, can be manipulated with only lings, cheating’s, worst practice recommendations, false / fake affirmations. I can’t’t believe that professionals in the most qualified science in the world, the science that put the man on the Moon, the science that give the PC, iPhone. The electronics sciences, can be fooled by some amputated brain ignorant’s thefts. It is unbelievable.

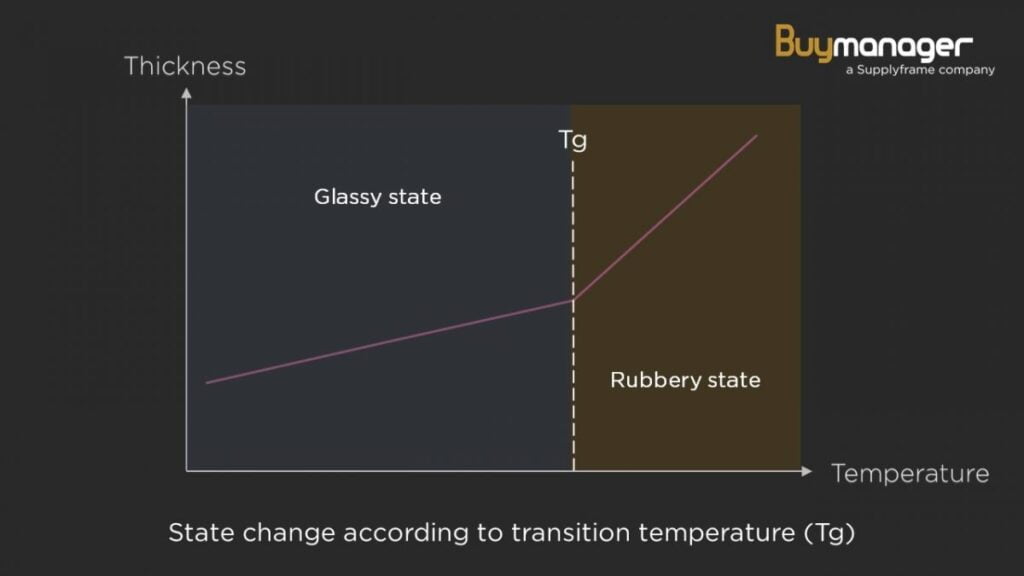

Let’s explain for you the Tg – point. Heating the PCB above this Tg – point, it is the worst and most common error. All “professional manufacturers”, “well-known manufacturers” make this error.

As you see from above image the Tg it is a point where the PCB change his state from solid – “Glassy state” (glass like) to “Rubbery state” (elastic state like a rubber). From here come the “Tg – point”. Every time that your PCB / board, BGA / chip are heated above that temperature (Tg – point) will expand until touch the Tg -point.

When touch and exceeds the Tg – point transform their state from glassy mode to rubbery mode and stop expanding (because will be elastic) but take the new shape / dimensions / form. When you cool the PCB / board / BGA / chip, these things will contract. But will contract from new dimensions / shape / form.

These expansions / contraction (from a scientific / technological point of view) almost sure that will destroy your VIAS (as chain theory say… “a chain will break at the weakness link”)… Well… your weakness link on this case are the VIAS. The VIAS are the small copper plated holes that make electrical connection between various copper layers trace on your board.

This fail, it is possible that does not manifest immediately… But almost sure that in the future you will have the worst ever defect in electronic… The intermittent failure – almost impossible to repair…

So… you MUST avoid with all price to heat the PCB / board over Tg – point. In the service repair of electronic, it is impossible to know what kind of PCB / board you have (FR-*) and on FR series the Tg – point can vary from about 110 °C to 180 °C. So… if you don’t know what FR-* you have, the best practice is to avoid heating the PCB / board over 100 °C.

Seems that in the world the Tg – point is unknown, that unknown of Tg – point can explain that over time (for about 35+ years) was used only technologies that don’t respect that Tg – point. The truth is that when I’ll start the documentation / learning about BGA Rework process, even I don’t know anything about this Tg – point. In fact, knowledge about that Tg – point it’s NOT the debt of knowledge of the clients that use a BGA Rework Station. For that, was invented the engineers that all “well-known, professional manufacturers” claim that have.

They MUST inform potential clients about Tg – point and the RISK behind that Tg – point.

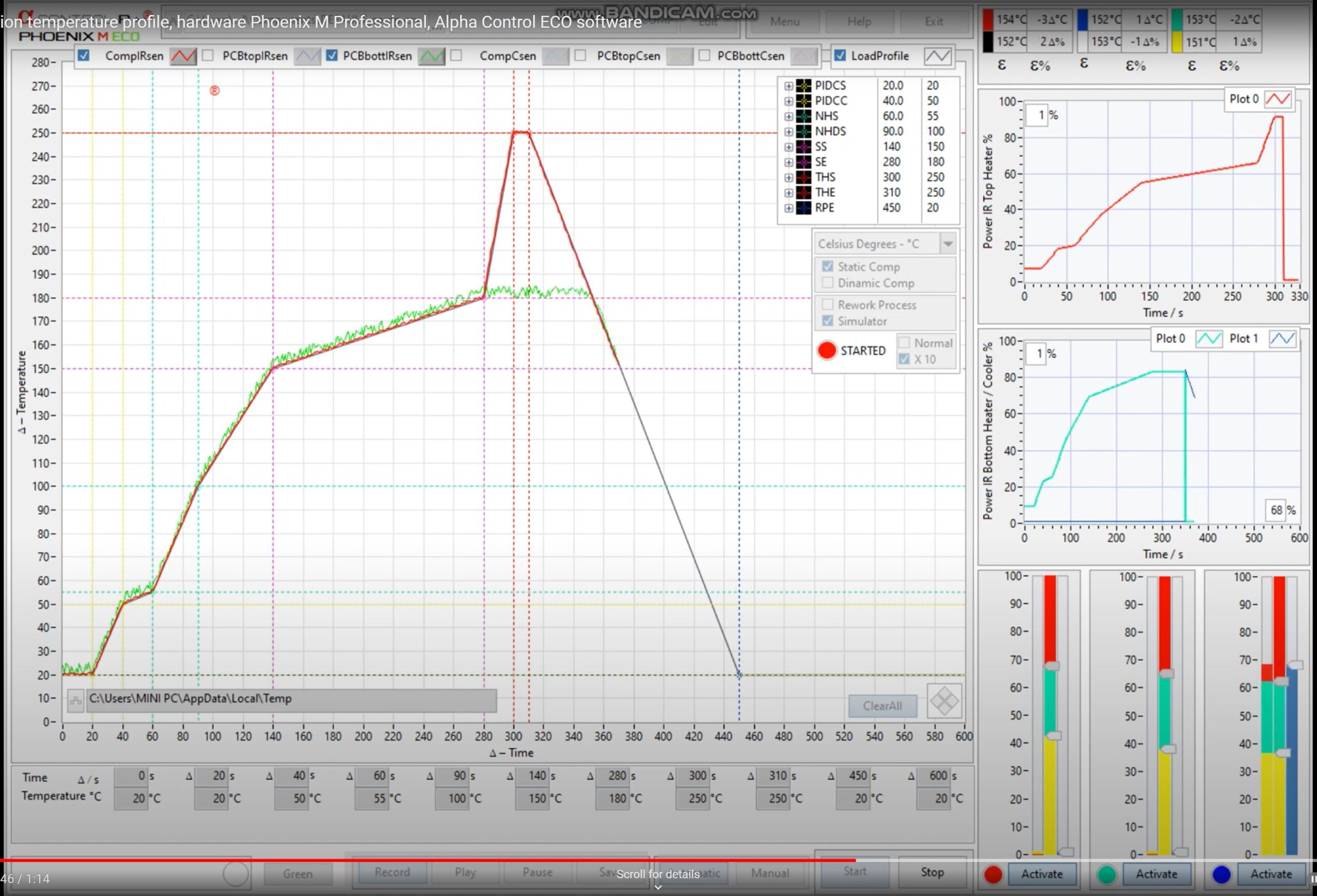

Above image is from my collection from early tests (2018… if I’ll remember correctly). You can find a small video here, link to video on YouTube. In that video, I test how visually are seen ±1 °C and ±2 °C accuracy. The red graph are from top – heater and green are from bottom heater. The PCB / board that I’ll use on that test was a FR-4 high temperature, with the TG – point around 180 °C. But… even that I’ll respect that Tg – point – 180 °C the PCB / board was in rubbery state (probably was a low quality PCB / board material).

At this time I decide that ever never I’ll outdated 100 °C to avoid all RISK that unnecessary stress the PCB / board.

So… You’ll have to choose from two point of view. As Hamlet (William Shakespeare) say… “To be… Or not to be…” This is about you, you MUST choose, to be professional, or… not to be professional. Middle ways don’t exist. Be professional mean best practice, all another ways (choosing’s) mean worst practice. That garbage’s that exist nowadays on the market are worst ever practice possible. Here, at the method for PCB / board – BGA / chip heating are more problems that we need to speak.

1 – Worst ever practice / worst ever approach – Finetech Jacuzzi® – When they are heating the PCB / board, BGA / chip with hot air / hot gas / nitrogen – details – click or touch or use menu to go.

Well… as almost all heat the PCB / board – BGA / chip with hot air / nitrogen capable… You’ll ask with what can be heated in the PCB / board – BGA / chip. The answer is simple (always the simple things are the best). You need to send to the PCB / board and independent to BGA / chip some kind of highly controlled “magic” electromagnetic energy. When that electromagnetic energy touches your PCB / board – Bga / chip… that objects will absorb that electromagnetic energy and will self heating (highly controllable / controlled).

So simple. With this method, you can control at 1 °C accuracy the temperature among your PCB / board – BGA / chip.

1 – Best practice – Direct Energy Transfer® – generate / send / receive pure energy and self heating the PCB / board – BGA / chip with the highest accuracy ever – details – click or touch or use menu to go.

Below, you have a clear example of how Finetech are trying to manipulate the self-titled “intellectuals” from electronics industry, giving an example with a gentleman that it is “Prof. Dr.-Ing. habil” Alexander Kolpin. As if you are lower in titles that this guy, you must be conformist and choose what this genius choose… A Finetech garbage to do your job. In this case, this “Prof. Dr.-Ing. habil” Alexander Kolpin or are ignorant about using his name on the Fintech website, or are ignorant in physics, electronics, mathematics, sciences, technologies subject.

What I can understand is that you’ll have a good thing, a good approach, a good vision, and you want to destroy the competence… You van use NASA, “Dr. Ing habil” and so on techniques to accent your best things.

But… when you are the one of the world’s worst ever practice approaches, to stain someone’s face with your garbage’s approaches… That is an ugly approach.

But as they “well-known, professional, Chinese” manufacturers use any possible manners (lies, cheating and so on…) to stole your money… Well… nothing can be surprising on Finetech.

In fact that garbage type approach we can find in all and every “well-known, professional, Chinese” manufacturers, in his money hungry fights to copy / paste same aberrations, worst practice approaches, lies, cheating’s and so on.

In fact, about Finetech garbage don’t deserve to speak more, They start the aberrations / worst practice chains with using hot air / hot nitrogen (“nitrogen capable bullshit”). Continue with some voodoo equation to guess the PCB / board, BGA / chip temperature over some T-type thermocouples. Next… continue with generating an “aliens” like sound when that garbage is start. Among that, they copy / paste famous errors from Zephyrtronics. In the future, time dependent, I’ll try to detail / change / organize the information on this page.