BGA Rework Stations - BGA / Chip - top-heater - worst practice approach "well-known, professional, Chinese" use.

Worst approach for heating of BGA / Chip. Convection / "Black-IR", "Focused Light".

All “well-known”, “professional, Chinese manufacturers”, use only the worst approach to heat a BGA / Chip. They don’t know anything about science, materials technology, best practice and more. In fact, they only copy / paste same errors, aberrations, promiscuity one from another. For more than 35 years for all them the only important are the money. The methods they’re used to making money, lies, cheating, pseudo-science, pseudo-technologies, steal, are not important.

When they, “well-known”, “professional, Chinese manufacturers” intend to sell us pizza machines, popcorn machines, Santa Claus cousin, as BGA Rework Stations they steal money from our packets. So simple, and somebody must stop that. The law is universal. It is that only a question of time that the buyers of that garbage stop to blame himself for the destruction that leave behind. The “professional, Chinese manufacturers” destroy me two PCB – about $7000.

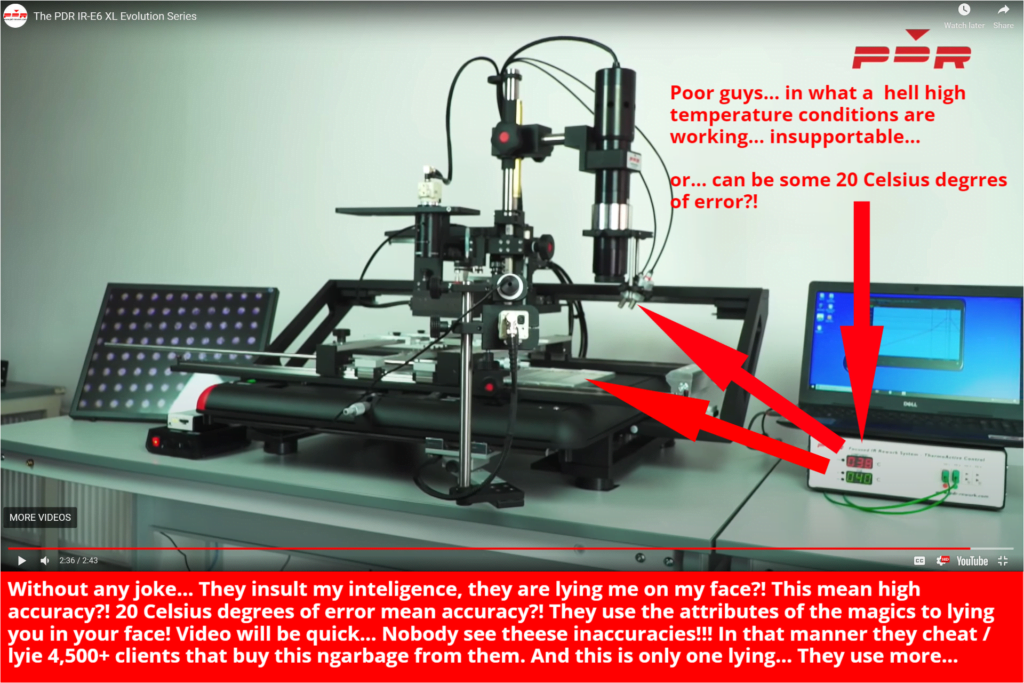

Worst ever approach temperature measurement of BGA / Chip. Zero accuracies approach.

On the money hungry competition, the “well-known”, “professional, Chinese manufacturers”, they all, use all kind of improper tools to measure one of the most important parameter when we speak about accuracy / quality, the temperature. But… Not only they use that, but they present on their webpages, on their YouTube channels all kind of aberrations, all kind pf promiscuity. They think that we’re blinds, that we are an amputated brain heard monkey horde / horde.

Worst ever approach heating control of BGA / Chip. They invent aberrational controls.

Not only that they, “well-known”, “professional, Chinese manufacturers”, steal us with the hardware that they are trying to sell us, but they try to sell us aberrational / irrational / promiscuous control, pieces of software. They invent standards, profiles, on-off methods, “focused light” non uniformizes… and much more. They think that for us, all aberrations, pseudoscience, worst practice that they employ on hos “products” are some alien things that we can’t judge.

Furthermore, they employ, NASA implication, awards, big success names, garbage approach in marketing.

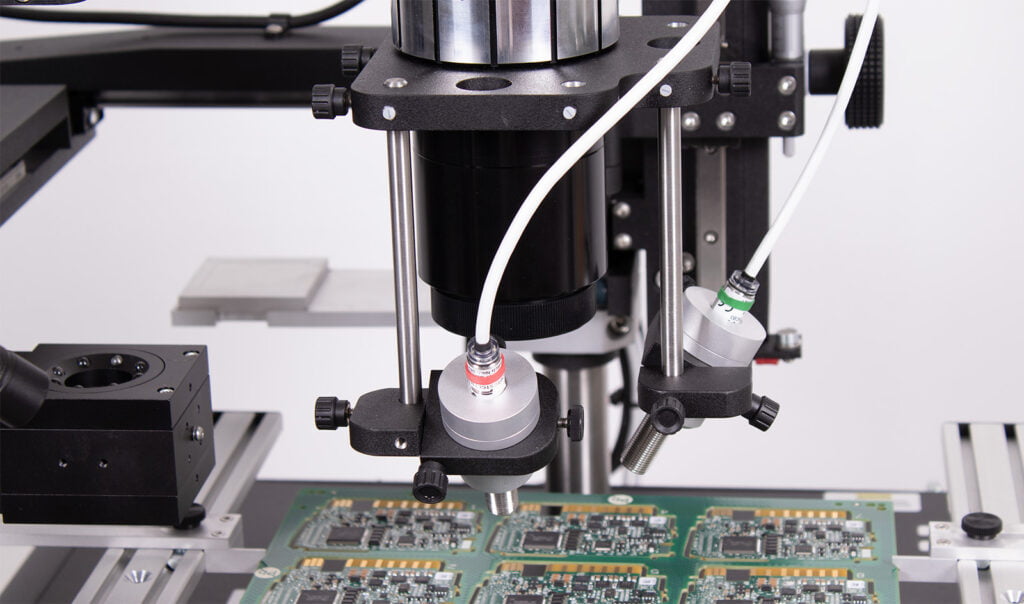

Let's speak about the worst ever approach for Top-Heater from part of "well-known, professional, Chinese" manufacturers.

I’m a guy that come from a highly specialized / qualified electronic service field. Years ago, when I’ll was short in money, I’ll was obliged to buy my first multimeter (a Chinese, cheapest one). At that time, I know that worth nothing but… was what I’ll have at that moment. I think… when I’ll grow up (in money), I’ll change it. After a while, I’ll change it with a Fluke – 289. In that same time, I’ll was obliged to buy my first oscilloscope (a Chinese, cheapest one). At that time, I know that worth nothing but… was what I’ll have at that moment. After a while, I’ll change it with a Fluke – 190-202 SCOPEMETER.

On the same path as above, I want to buy a BGA Rework Station. At that time for me was a MUST-have. I’ll do a search on the internet for a Chines’ garbage – I’ll fund… nothing. I look at “well-known” / “professionals” manufacturers… First that I’ll see was the garbage unjustified prices for same worst approach, and the fact that are same miseries like Chines’ manufacturer’s worst approach. So far so good… But I need a real Professional BGA Rework Station. What can I’ll do ?! I’ll wait… For some years… Meantime I’ll study from scientific / technological point of view, best approach. That was between 2012 and 2017.

I’ll wait until 2017. In that year was enough waiting. In that years, between 2012 and 2017 I loose a huge amount of money due to the fact that I’ll don’t have a Real Professional BGA Rework Station. But I learn so many things in physics, material technology, best approaches and so on… in fact I learn / understand what I need from a real Professional BGA Rework Station. On 2017 still, I needed A Real Professional BGA Rework Station. On 2017, I’ll start few projects about BGA Rework stations, from two points of view – worst practice ever (all “will-known”, “Chinese”, “Professional” manufacturers) and best practice – science / technologies / logics / electronics (click or touch to go).

In 2017, after that I’ll see that all “well-known”, “professional”, “Chinese” manufacturers does same things – copy / paste same errors, same aberrations, same worst practice ever… I decide to put in practice all my results derived from my past researches. I probe / test from theoretical and practical point of view, all and every worst practice / approach ever that all manufacturers use. That worst practice / approach ever, MUST not be used on electronics, on BGA Rework Stations. Below you’ll have my theoretical / practicals that I’ll discover about worst practice approach that all “well-known, professional, Chinese” have.

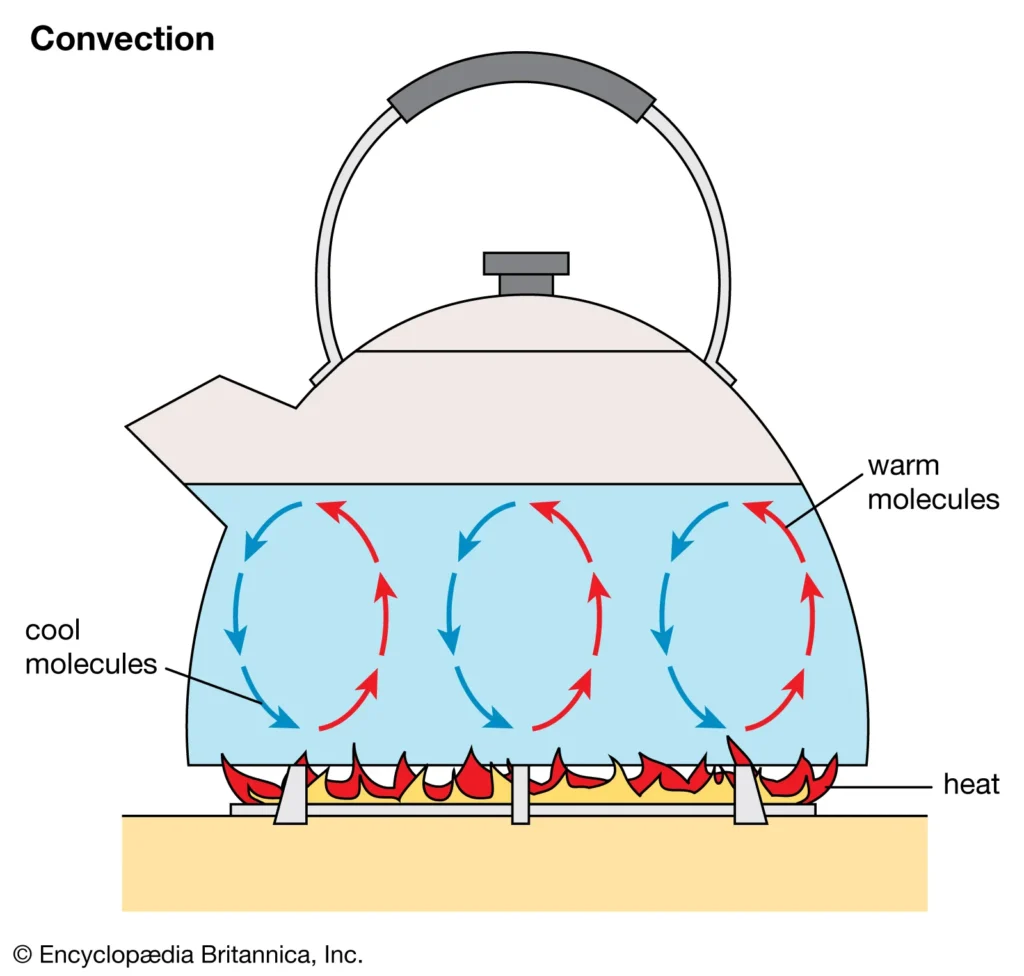

Convection method of heating the BGA / chip, worst ever approach to heat BGA.

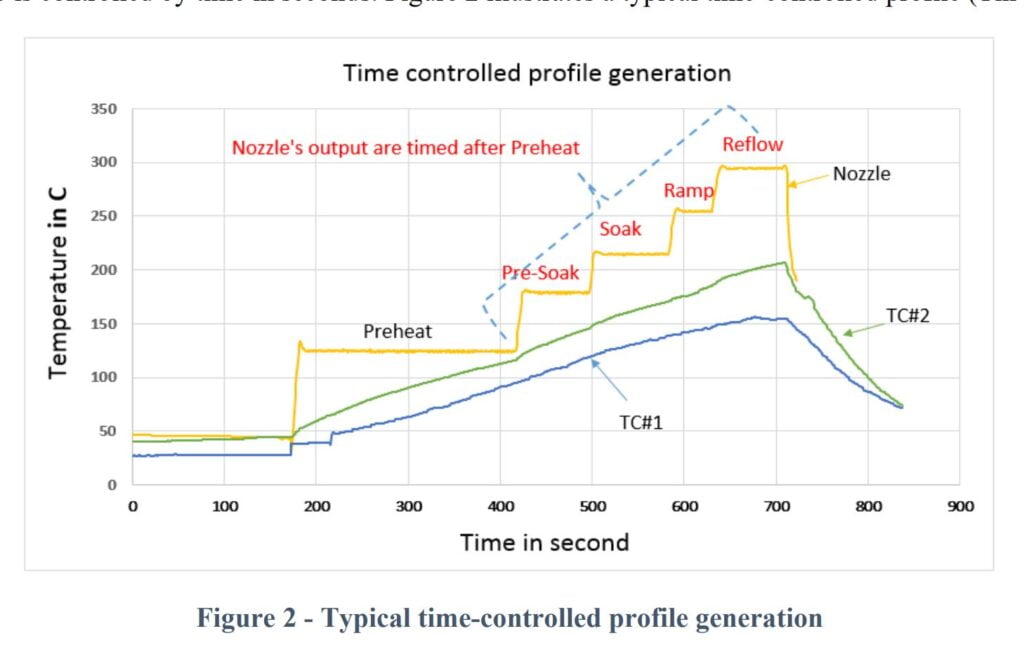

Direct convection heating of a BGA / chip, is the worst ever approaching method that can be used. That conversion mean that something is heated at high temperature (600 °C to 900 °C) and with a medium (air or nitrogen using blowing) is transported to the BGA / chip. In fact, the air / nitrogen heat the BGA / chip. Here enter hot air / nitrogen, “Black-IR”, hybrid top heaters.

Another approach (the best approach) are use by PDR-Rework (“Focused Light”) and some Chinese manufacturers.(both use this method in an uncontrolled way), so… are completely unusable.

Direct convection heating, "Black-IR". MWIR, "Focused Light", MUST do not be used to heat a BGA / Chip.

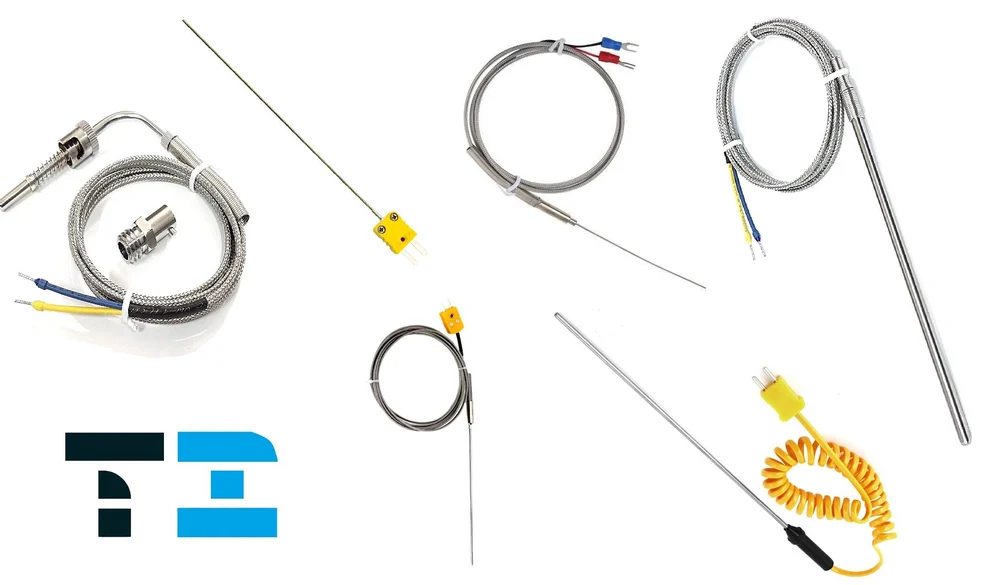

Temperature of BGA / chip reading the worst ever approach, K-Type, IR-sensors.

Generally speaking, at this time, two approach are used to read the temperature of BGA / chip. First approach is K-Type thermocouples temperature reading for contact approach of temperature reading. Worst ever type of thermocouple. All they claim ± 1 °C, That’s the biggest lies on the world and remain only that without proofs (NIST – traceable certificate).

The second approach is the non-contact-IR temperature reading. That approach generate the worst accuracy reading due to the fact that the non-contact-IR sensors are highly dependent of IR-emissivity of the object – the BGA / chip. Need compensation.

K-Type thermocouple MUST do not be used in none temperature measurement. The non-contact-IR sensors, MUST be dynamically compensated.

Hot air / Hot gas (hot nitrogen) - the worst ever approach

Hot air use the infamous direct convection heating, the worst ever approach. To heat at… let say… to heat around 250 °C, a BGA / chip, the hot air MUST have more elevated temperature, around 320 °C to 400 °C, blowing air speed dependent. At that temperature, the BGA / chip will be popcorn and surrounding heat sensitive components will be exploded.

And… if you don’t blow uniform the air on top of the BGA, the BGA will lean to one side. This approach is one of that approach that MUST not be used on a real Professional BGA Rework Station. That technology (hot air), in fact, is used by NASA to heat hamburgers and pizza in space. That is a best practice approach… heating hamburger and pizza.

If you don't want popcorn BGA / chips or exploded surrounding heat sensitive components, you MUST don't use hot air / hot nitrogen.

Black - IR (LWIR) - the worst ever approach

Another candidate to popcorn / explosion phenomena. Among hot air, the “Black-IR (LWIR)” use direct convection to transport the heat from the emitter to BGA / chip. But… This”” Black-IR (LWIR) have something more (worst) than only hot-air / hot nitrogen. It has HUGEST ever inertia and closest possible position to BGA / chip!!!

That mean that when you start this monster… you can say goodbye to BGA / Chip and all surrounding components that this energy can touch.

This is the highest aberrational top heater approach. In fact… due to his huge inertia, this type of heater is used to maintain the food hot.

MUST be avoided with all prices, the using of that type of destruction top heater on a real Professional BGA Rework Station.

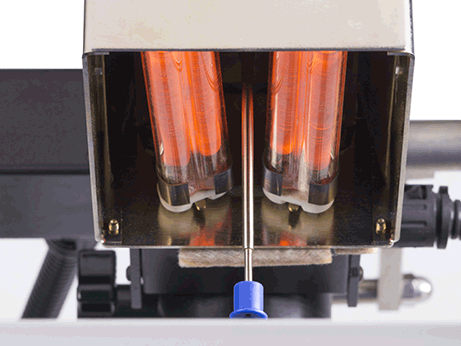

MWIR - almost the worst ever approach.

That… MWIR are used on some models of Pace garbage manufacturer. That MWIR are close to the less damaging Infra Red wave part spectrum until now. But… as the Pace use that MWIR heater… produce same or more damages that Black-IR heater described above. That type of heater have less inertia (still are big inertia) to control. But as I write above… are not adequate for a real Professional BGA Rework Station.

In fact, that technology is used in high and very high temperature kilns (for metal, ceramic and so on…)

Must avoid being used in a Real Professional BGA Rework Station.

Nozzle shapes for hot air / hot nitrogen.

These things, you can’t believe me, you’ll never ever have the right dimension.

The BGA / chips manufacturers create an infinite “honey pot” for those that sell nowadays garbage to rework a BGA. They give to “well-known”, “professional, Chinese manufacturers” the opportunity to make money forever… with shapes / dimensions for the BGA / chips. So… after you’ll spend a small or big fortune to destroy PCB’s / BGA / boards / chips, now you need the “tip” for your weapon. Never ever will stop from money hungry…

I love that, after that all "well-known", "professional, Chinese manufacturers" sell garbage... want more... money!!!

Contact K-type thermocouple temperature measurement, the worst ever approach.

On his datasheet, the theory says that the accuracy of that type of thermocouple are between ± 2.5 °C. Seems that can be good. False. Even that, verified in practice are true, is not enough. But verified in practice, buy me is more than ± 15 °C. That is huge. In fact, this K-Type of thermocouple are used on high temperature applications.

Like (kilns / forge for metals, ceramic kilns and so on), where is need high temperature, around 1200 °C, where ± 15 °C accuracy are not so important. Here, on BGA Rework Statins, we need at least ± 1 °C of accuracy. So… MUST be avoided the use of that kind of thermocouples.

The K-Type thermocouples MUST do not be used on BGA Rework Stations for contact approach of temperature measurement.

Non-contact-IR sensors temperature measurement the worst ever approach.

Despite that the Non-contact-IR sensors are the best approach to measure in non-contact mode, the temperature, they are the most difficult to use in a best practice approach. They have a peculiar attribute, “object emissivity” that ca vary from 0.1 to 0.9.

For that reason, this type of sensors must be “dynamically compensated”. If are not “dynamically compensated”, a temperature… ;et say about 100 °C – real, will be measured by non dynamically compensated, non-contact IR sensors from ± 1 °C to 90 ± °C. Until now, nobody compensates them. But someone’s use them, uncompensated.

Non-contact-IR sensors MUST be dynamically compensated, if not, MUST not be used.

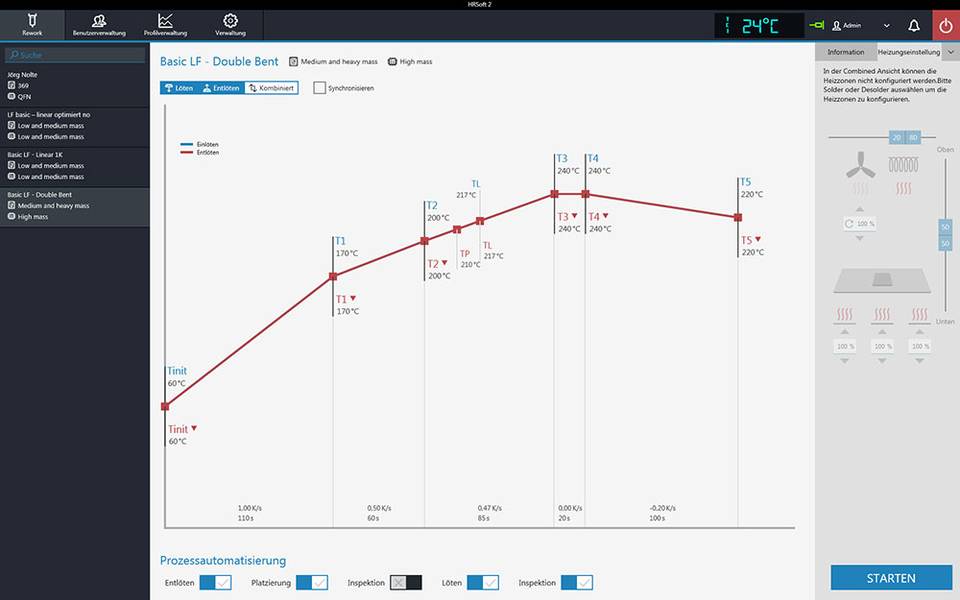

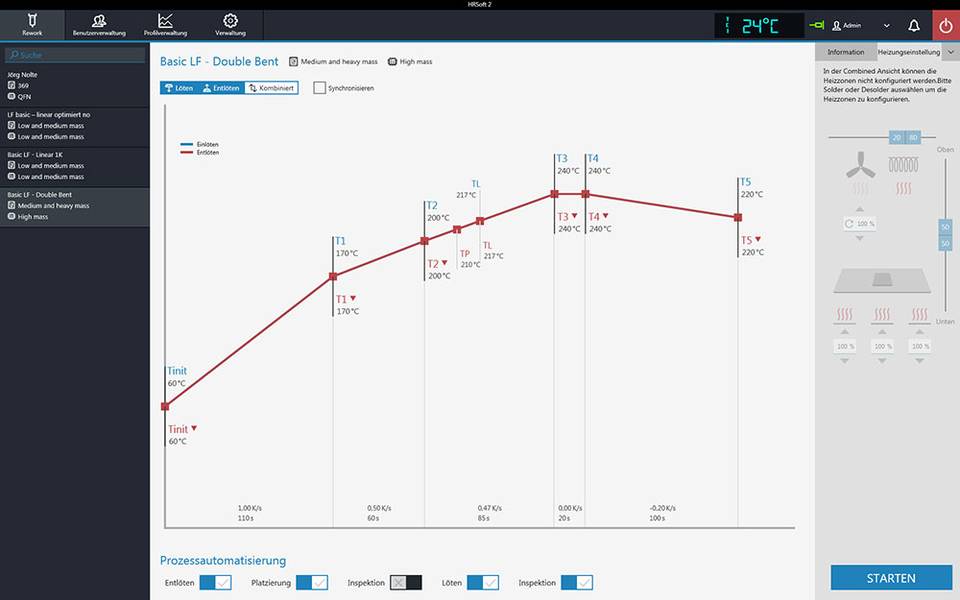

Temperature control for BGA / chip the worst ever approach

That it is for laughs. They even don’t know that the pseudo technologies that they use to manufacture garbage, are uncontrollable, it is impossible to control them in that manner!!! Well, as they don’t know that… try to control them and… can’t. Well… if they can’t control that garbage… they invent new approaches, new standards, new aberrational programs, new promiscuous Reworks Profiles and so on…

They invent anything that present’s on the market with hard “makeup” of false / fake marketing, only to sell his garbage. Money hungry policy. Nothing more.

We need to respect standards, not create standards as our control... can do the things.

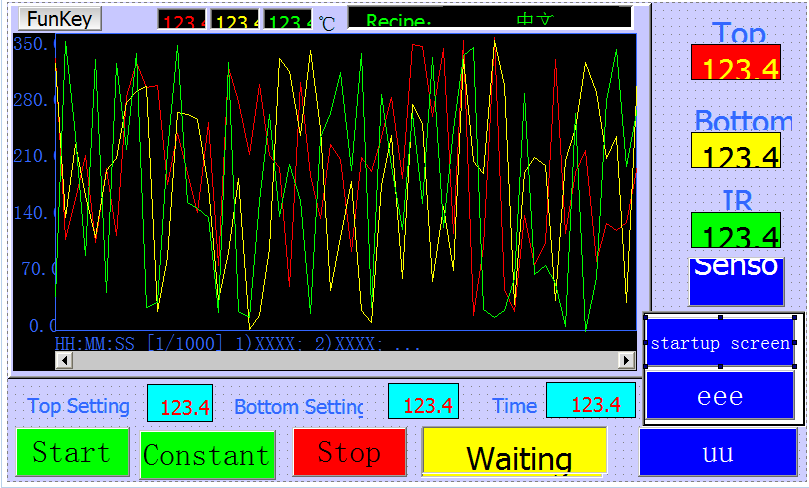

Temperature control - On / Off the worst ever approach

To think that you can do on / off with a 800W power resistance, you need to forget the inertia. Unfortunately, the inertia of a system (as physics science say…) can’t be ignored, only due to the fact that all systems have inertia. Some systems huge inertia, some systems small inertia.

That system with hot air / hot nitrogen / Black-IR, MWIR… All of them have a HUGE inertia. To stop and start some kind of system, you need tens of seconds, about 10 to 40 seconds.

A best practice approach for control system must act in 0.1ms.

That on / off method is inappropriate to use in a real Professional BGA Rework Station.

Temperature control - continuous control the worst ever approach

This guys, “well-known”, “professional, Chinese manufacturers” are awesome!!! They employ some voodoo equations combined with some Nostradamus predictions to evaluate, in the future, the temperature that BGA / chips will have. They slowly step up the power of the top-heater and hope…

That the temperature of the BGA / chip will follow this policy. No sir… will not follow. You must use science, technology, best practice to do that.

If so… Well… the temperature will always follow a good – AI assisted Fuzzy logic PID!!! But… you don’t know anything about that…

To really accurate control the top-heater, we need Artificial Intelligence controlled Fuzzy Logic Proportional - Integral - Derivative algorithm.

Heating uniformity the worst ever approach

Even with hot-air / hot nitrogen or MWIR or Black-IR, the uniformity is best that PDR-Rework and some Chinese “Focused Light.”

PDR-Rework with 35+years of experience (I wandered… in what…) don’t understand the difference between… focused (that is used in laser to cut) and diffused… that mean UNIFORM DISPERSED among entire perimeter of the BGA. In fact, what we can expect from PDR-Rework part?! They live with the idea that the BGA / chip is round!!! And they believe that for 35+ years!!!

For some time join them some weirds Chinese, that discover the gold-plated reflector halogen bulb… But… the Chinese are the best!!! Use a 250W bulb – burn / explode all. PDR-Rework can’t. They spend their 150W of power in… heating 8 lenses!!!

I'll bet that the PDR-Rework, on this century will not realize the fact that the BGA / chip is square, rectangular or any other shape can have... Only round will not be...

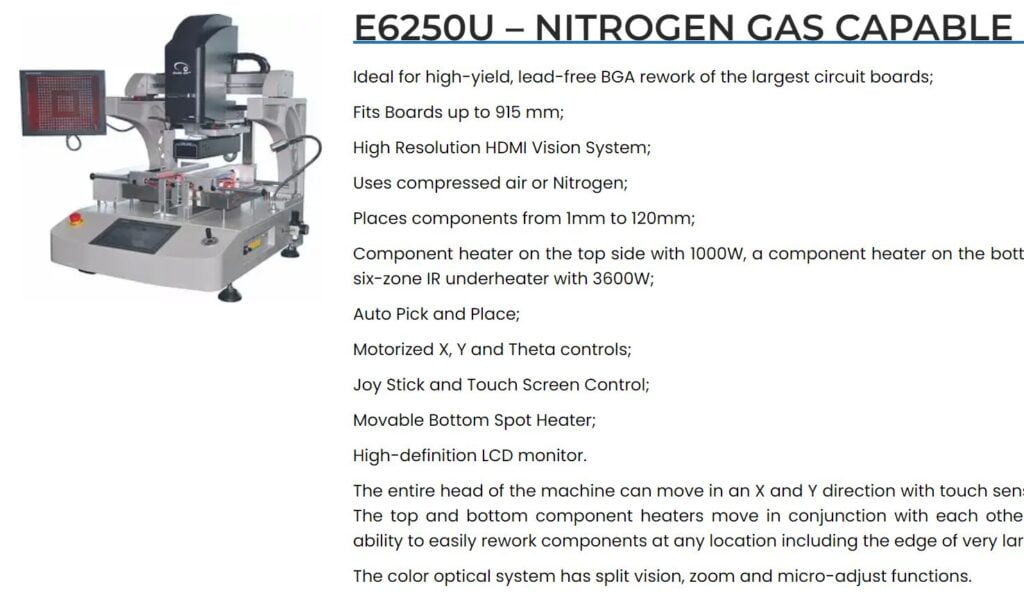

"Nitrogen capable" - the worst ever stupid marketing invention!!!

Science… say something about gas pressure equilibrium… In short, the science says that a system is in equilibrium will remain in equilibrium if we don’t change that equilibrium. Have logic…

Well… the air that exist between PCB and BGA are in a pressure equilibrium. Can somebody explain for me… how can be broke that equilibrium when they’re blown uniform from all sides, nitrogen?! The equilibrium can be broke only if they blow nonuniform from all sides, the nitrogen.

Well… if that occur… the nitrogen anti oxidation effect are useless… because the BGA are… Nonuniform soldered (will lean to the side where the pressure is great) and the ball with high pressure will be soldered, where are low pressure will be in air / not soldered.

But the important is... the marketing aberration that the garbage is... "nitrogen capable"

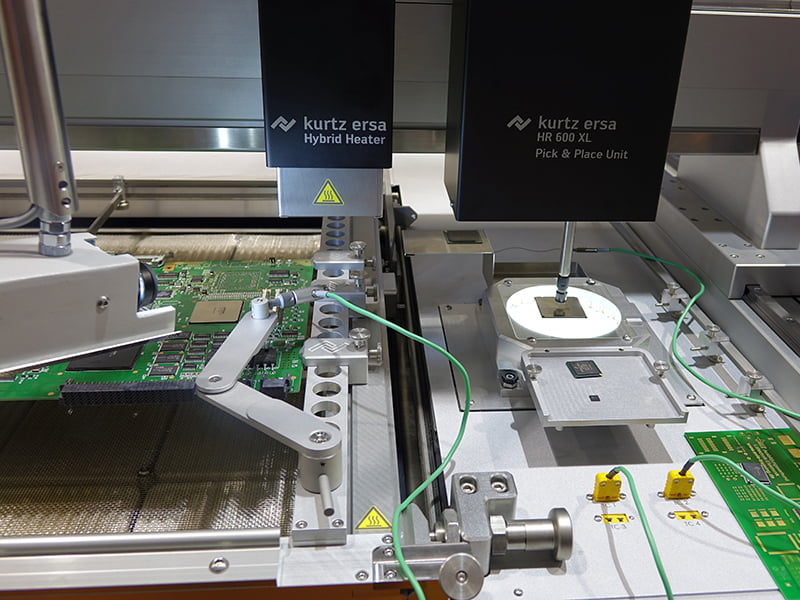

Hybrid invention - the worst ever approach Kurtz-ERSA patented aberration!!!

As usual, KURTZ-ERSA it is in front. It is in front of the best aberration ever competition. They are not alone, many other claim hybrid, but KURTZ-ERSA outperforming them all. They use… Black-IR (or MWIR) mixed with hot air / hot nitrogen.

They think… If the IR can’t solder the metallic top BGA (as passed with PDR-Rework), well… KURTZ-ERSA can!!! With hot air / hot nitrogen from his “hybrid” aberrational invention.

That guys… are awesome. They spend in Research and development for garbage that they manufacture a huge amount of money and the result is about… 6 to 8 garbage models.

With only a fraction that they invest in garbage R&D, I’ll have 6 projects. But… I’ll spend my money… I’ll respect my money. KURTZ-ERSA… spend your money… this is a round business.

Never ever these types of "hybrids" can be used on a real Professional BGA Rework Station.

Please, read with attention all information on this website and the sister website… BGA-Rework-Station.com (click or touch the link to go…). If you’ll see that message, I’ll work on that website to build them. Please be patient.

Please, read with attention all information on this website and the sister website… BGA-Rework-Station.com (click or touch the link to go…). If you’ll see that message, I’ll work on that website to build them. Please be patient.